Why Build a 18650 Battery Pack Yourself?

18650 lithium batteries offer high energy density, long cycle life, and affordability. They’re widely used in electric skateboards, portable power stations, solar storage systems, and power tools. DIY battery packs allow you to customize voltage, capacity, and size to perfectly fit your devices.

However, building your own pack comes with risks. Errors like poor connections, inadequate insulation, or using the wrong BMS can cause failure or danger. Basic electrical knowledge and strict safety awareness are essential.

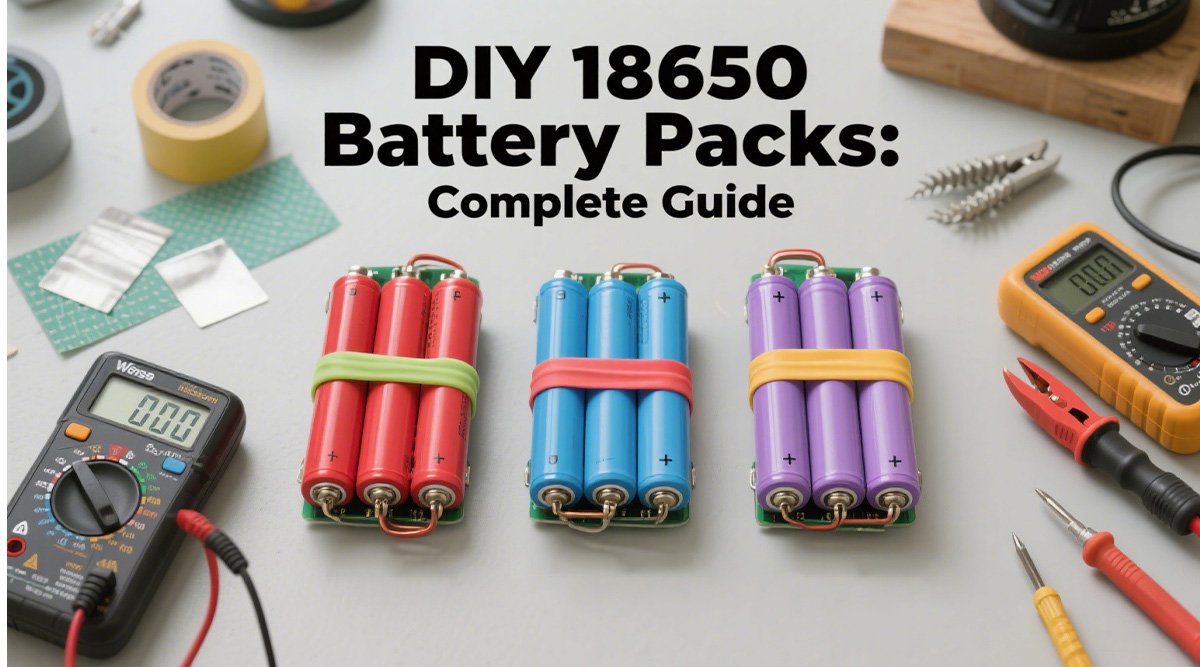

Preparation: Materials and Tools Needed

Materials:

- 18650 lithium cells (choose ones with similar capacity and internal resistance)

- BMS (Battery Management System) suitable for your series count and discharge current

- Nickel strips or nickel-plated copper strips

- Battery holders or hot glue

- Fish paper, insulating tape, heat shrink tubing

Tools:

- Spot welder (preferred) or high-power soldering iron

- Multimeter and internal resistance tester

- Heat gun/hair dryer, scissors, battery casing or PVC wrap

Cell Testing and Grouping

Before assembly, test each cell to ensure similar capacity, voltage, and internal resistance. Mismatched cells can cause imbalance and shorten the battery pack’s lifespan.

Testing Procedure:

- Use a capacity tester to discharge each cell

- Record voltage and internal resistance, then group matching cells together

- Avoid mixing old and new cells or cells with major capacity differences

Designing Series and Parallel Configurations

Basic Concepts:

- Series (S) increases voltage: e.g., 3S = 11.1V, 4S = 14.8V

- Parallel (P) increases capacity: e.g., 2P = 2×capacity, 3P = 3×capacity

Examples:

- 3S2P: Three series groups with two cells in parallel → Total: 11.1V and 2× capacity

- 4S3P: Four series, each with three cells in parallel → 14.8V output and 3× capacity

Always design based on your device’s voltage, power, and current requirements.

Pack Assembly and Spot Welding

Step 1: Arrange the Cells

Use holders or hot glue to fix cell positions. Stagger positive and negative terminals for easier welding.

Step 2: Spot Weld Nickel Strips

Use a spot welder to connect nickel strips:

- First connect parallel groups

- Then connect the groups in series

Avoid short circuits and never let positive and negative terminals touch directly.

Step 3: Check Connections

Ensure strong welds and verify current pathways with a multimeter.

Installing and Wiring the BMS

The BMS (Battery Management System) manages charging and discharging, providing overcharge, over-discharge, and balancing protection.

Wiring Notes:

- B- connects to battery negative

- P-/P+ connect to pack output negative/positive

- B1, B2, B3… connect to each cell group’s mid-point (voltage taps)

Refer to the BMS wiring diagram specific to your model.

Insulation and Pack Sealing

Recommended Materials:

- Fish Paper: Insulates conductive surfaces to prevent shorts

- Foam Pads: Absorb vibration and prevent cell wear

- Heat Shrink or PVC Case: Wraps the pack for mechanical protection

Thorough Insulation Tips:

Pay extra attention to terminals, exposed wires, and the back of the BMS board.

Initial Charging and Function Testing

Before charging, use a multimeter to confirm voltage consistency across cell groups.

Recommendations:

- Use a constant current/constant voltage (CC/CV) charger

- Check if BMS activates properly during charging

- Test discharge with a load like a fan, light bulb, or motor to confirm stability

Safety Guidelines and Best Practices

- Never use damaged or swollen cells; don’t disassemble sealed packs

- Avoid overcharging/over-discharging—always pair with a proper BMS and charger

- Keep away from sharp metal objects; use foam or hard shell for transport

- For long-term storage, keep the charge around 50% and store in a cool, dry place

Common FAQs

| Question | Answer |

|---|---|

| Can I mix old and new batteries? | Not recommended—it causes imbalance and shortens lifespan |

| Can I use a soldering iron instead? | Barely—risk of overheating cells and damaging them |

| Is it safe to skip the BMS? | No—BMS is critical for safety and performance |

| How do I know if the welds are solid? | Measure voltage, check for loose welds, and observe for abnormal heating |

| What cell brands are recommended? | Samsung, Panasonic, LG, BAK, Lishen, and other reputable brands |

Conclusion: The Rewards and Responsibilities of DIY Battery Building

Building your own 18650 battery pack is both satisfying and functional—but it requires caution, skill, and responsibility. Start small with low-current, small-scale packs, follow all safety protocols, and keep learning as you go. With care, you can enjoy reliable performance and tailored energy solutions from your own creations.

Leave a Reply