Solid-State Batteries: Industry Overview and Future Trends

Lithium-ion batteries are reaching their limits in terms of energy density and safety. Thermal runaway risks remain a major concern, especially as demand for higher energy storage continues to rise. To address these issues, solid-state batteries have emerged as a promising next-generation solution.

Unlike traditional batteries that rely on flammable liquid electrolytes, solid-state batteries use solid electrolytes to conduct lithium ions. This change not only improves safety but also enables the use of higher-capacity electrodes, unlocking much greater energy density. Around the world, companies are racing to bring this technology into mass production, with the potential to reshape the entire battery industry once commercialization takes off.

In this article, we’ll look at the concepts, advantages, and challenges of solid-state batteries, examine current industry developments, and explore where the technology is heading.

I. Industry Overview

Concept

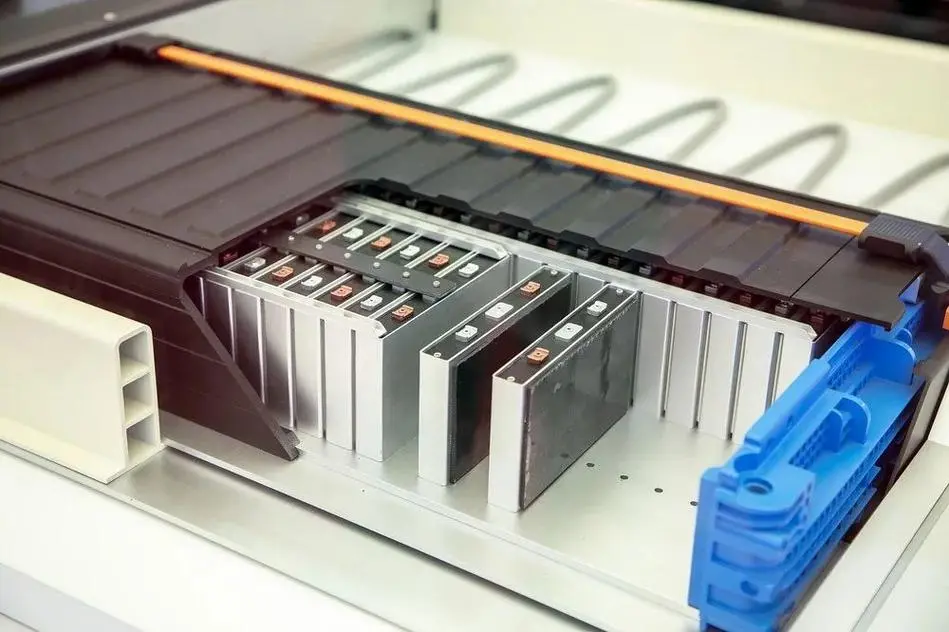

Conventional lithium-ion batteries consist of a positive electrode, a negative electrode, a liquid electrolyte, and a separator. The liquid electrolyte allows ion transport but is also flammable, corrosive, and unstable under high voltage, creating safety concerns. It also cannot fully prevent lithium dendrite growth, which can pierce the separator and trigger short circuits.

Solid-state batteries replace part or all of the liquid electrolyte with solid electrolytes. This substitution improves both safety and energy density, making them one of the most promising long-term technologies.

Classification

Batteries can be categorized based on the proportion of liquid electrolyte:

- Liquid batteries: ~25 wt% liquid electrolyte

- Semi-solid-state batteries: 5–10 wt% liquid electrolyte

- Quasi-solid-state batteries: <5 wt%

- All-solid-state batteries: 0 wt% liquid electrolyte

The last three are collectively referred to as solid-state batteries. Depending on material type, solid electrolytes are generally classified into polymers, oxides, and sulfides.

Semi-Solid-State Batteries

Compared with liquid batteries, semi-solid batteries reduce the amount of liquid electrolyte used and combine it with polymer + oxide electrolytes.

- Polymers provide structural frameworks.

- Oxides mainly coat the electrodes.

- Negative electrodes evolve from graphite to silicon-based or lithium metal.

- Positive electrodes shift toward high-nickel or lithium-rich manganese-based materials.

- Separators are coated with solid electrolyte layers.

- Electrolyte salts move from LiPF6 to LiTFSI.

With these changes, energy densities of 350 Wh/kg or more can be achieved.

All-Solid-State Batteries

All-solid batteries completely remove liquid electrolytes, replacing them with polymer, oxide, or sulfide systems.

- Polymers are easier to process but limited in performance.

- Oxides are advancing rapidly.

- Sulfides are considered the most promising for the future.

In these designs:

- Negative electrodes transition fully to silicon-based or lithium metal.

- Positive electrodes move to ultra-high-nickel, nickel-manganese oxide, or lithium-rich manganese-based materials.

Energy densities of 500 Wh/kg or more are achievable.

Advantages and Disadvantages of Solid-State Batteries

Advantages

- High Safety

- Solid electrolytes are non-flammable and non-volatile.

- They reduce the risk of thermal runaway even under extreme conditions like overheating, piercing, or bending.

- High mechanical strength also slows dendrite growth, minimizing short-circuit risks.

- Non-Flammability and Thermal Stability

- Unlike liquid electrolytes that decompose around 200°C, solid electrolytes remain stable at much higher temperatures.

- This allows operation at higher charge/discharge rates and wider temperature ranges.

- High Energy Density

- Solid electrolytes can pair with high-capacity electrodes such as lithium metal and silicon anodes or high-voltage cathodes.

- Structurally, they replace the role of both separator and electrolyte, reducing electrode spacing and increasing energy density.

- At the battery pack level, solid electrolytes allow for tighter integration and lighter thermal management systems, further boosting volumetric energy density.

Disadvantages

- Low Ion Conductivity & Poor Cycle Life

- Solid-solid interfaces have limited contact and higher resistance than liquid-solid interfaces.

- Volume changes during cycling can cause cracking, poor contact, and rapid capacity loss.

- High Cost

- Solid electrolytes often require expensive raw materials (e.g., zirconium in oxides, germanium in sulfides).

- Current electrode materials designed for high energy density are not fully mature and add further cost.

- Production processes are more complex, demanding specialized equipment and tighter quality control.

II. Industry Status and Development Trends

Development Phases

- Phase One: Introduce solid electrolytes while retaining some liquid, with ternary cathodes + graphite/silicon anodes.

- Phase Two: Full solid electrolytes with lithium metal anodes, while cathodes remain ternary-based.

- Phase Three: Mature sulfide and lithium-rich cathode systems with thinner solid electrolyte layers.

Current Status

- Semi-solid batteries are already entering mass production, balancing safety, cost, and performance. They retain a small amount of liquid electrolyte, improving conductivity and making them compatible with existing lithium battery manufacturing lines. Costs are only about 10–20% higher than liquid batteries.

- All-solid-state batteries are still in the R&D stage, but mass production is expected around 2025, with commercialization scaling up by 2028.

Global Landscape

- United States: Startups lead the charge (Solid Power, SES, QuantumScape), focusing on polymers and oxides with fast commercialization.

- Japan: Strong government-industry-academia cooperation, heavily invested in sulfide-based technology. Key players include Toyota, Panasonic, Nissan.

- South Korea: Emphasizing sulfide systems with strengths in electrode materials. Key players include Samsung SDI, LG, SK Innovation.

- China: Automakers are partnering with startups (e.g., NIO with Eve Energy; BAIC, SAIC, and GAC with Qingdao Energy).

Automakers worldwide are investing in solid-state R&D, securing long-term supply partnerships to accelerate commercialization.

III. Production Process

Semi-Solid-State Batteries

Production is largely compatible with traditional lithium battery processes. Only about 10–20% of equipment needs modification, mainly for introducing solid electrolyte coatings and in-situ solidification steps. This compatibility makes semi-solid batteries the first to reach the market.

All-Solid-State Batteries

Production is more complex and less compatible with current lithium battery processes. Key differences include:

- Electrolyte processing: Requires sol-gel or other coating techniques, followed by drying and baking.

- No electrolyte injection step.

- Dry electrode processes are expected to play a major role, especially in sulfide systems where traditional solvent-based methods are unsuitable.

Conclusion

Solid-state batteries are widely seen as the ultimate successor to today’s lithium-ion technology, promising higher safety, higher energy density, and long-term scalability. While semi-solid batteries are already moving into production, full solid-state batteries still face challenges in cost, conductivity, and cycle life.

Nevertheless, with global automakers and battery manufacturers investing heavily, solid-state batteries are on track to enter commercial mass production by the middle of this decade, potentially reshaping the electric vehicle and energy storage industries.

Leave a Reply