Your cart is currently empty!

Category: Battery FAQ

-

How to Make Your Own 18650 Battery Pack: A Complete DIY Guide

Why Build a 18650 Battery Pack Yourself?

18650 lithium batteries offer high energy density, long cycle life, and affordability. They’re widely used in electric skateboards, portable power stations, solar storage systems, and power tools. DIY battery packs allow you to customize voltage, capacity, and size to perfectly fit your devices.

However, building your own pack comes with risks. Errors like poor connections, inadequate insulation, or using the wrong BMS can cause failure or danger. Basic electrical knowledge and strict safety awareness are essential.

Preparation: Materials and Tools Needed

Materials:

- 18650 lithium cells (choose ones with similar capacity and internal resistance)

- BMS (Battery Management System) suitable for your series count and discharge current

- Nickel strips or nickel-plated copper strips

- Battery holders or hot glue

- Fish paper, insulating tape, heat shrink tubing

Tools:

- Spot welder (preferred) or high-power soldering iron

- Multimeter and internal resistance tester

- Heat gun/hair dryer, scissors, battery casing or PVC wrap

Cell Testing and Grouping

Before assembly, test each cell to ensure similar capacity, voltage, and internal resistance. Mismatched cells can cause imbalance and shorten the battery pack’s lifespan.

Testing Procedure:

- Use a capacity tester to discharge each cell

- Record voltage and internal resistance, then group matching cells together

- Avoid mixing old and new cells or cells with major capacity differences

Designing Series and Parallel Configurations

Basic Concepts:

- Series (S) increases voltage: e.g., 3S = 11.1V, 4S = 14.8V

- Parallel (P) increases capacity: e.g., 2P = 2×capacity, 3P = 3×capacity

Examples:

- 3S2P: Three series groups with two cells in parallel → Total: 11.1V and 2× capacity

- 4S3P: Four series, each with three cells in parallel → 14.8V output and 3× capacity

Always design based on your device’s voltage, power, and current requirements.

Pack Assembly and Spot Welding

Step 1: Arrange the Cells

Use holders or hot glue to fix cell positions. Stagger positive and negative terminals for easier welding.Step 2: Spot Weld Nickel Strips

Use a spot welder to connect nickel strips:- First connect parallel groups

- Then connect the groups in series

Avoid short circuits and never let positive and negative terminals touch directly.

Step 3: Check Connections

Ensure strong welds and verify current pathways with a multimeter.

Installing and Wiring the BMS

The BMS (Battery Management System) manages charging and discharging, providing overcharge, over-discharge, and balancing protection.

Wiring Notes:

- B- connects to battery negative

- P-/P+ connect to pack output negative/positive

- B1, B2, B3… connect to each cell group’s mid-point (voltage taps)

Refer to the BMS wiring diagram specific to your model.

Insulation and Pack Sealing

Recommended Materials:

- Fish Paper: Insulates conductive surfaces to prevent shorts

- Foam Pads: Absorb vibration and prevent cell wear

- Heat Shrink or PVC Case: Wraps the pack for mechanical protection

Thorough Insulation Tips:

Pay extra attention to terminals, exposed wires, and the back of the BMS board.

Initial Charging and Function Testing

Before charging, use a multimeter to confirm voltage consistency across cell groups.

Recommendations:

- Use a constant current/constant voltage (CC/CV) charger

- Check if BMS activates properly during charging

- Test discharge with a load like a fan, light bulb, or motor to confirm stability

Safety Guidelines and Best Practices

- Never use damaged or swollen cells; don’t disassemble sealed packs

- Avoid overcharging/over-discharging—always pair with a proper BMS and charger

- Keep away from sharp metal objects; use foam or hard shell for transport

- For long-term storage, keep the charge around 50% and store in a cool, dry place

Common FAQs

Question Answer Can I mix old and new batteries? Not recommended—it causes imbalance and shortens lifespan Can I use a soldering iron instead? Barely—risk of overheating cells and damaging them Is it safe to skip the BMS? No—BMS is critical for safety and performance How do I know if the welds are solid? Measure voltage, check for loose welds, and observe for abnormal heating What cell brands are recommended? Samsung, Panasonic, LG, BAK, Lishen, and other reputable brands Conclusion: The Rewards and Responsibilities of DIY Battery Building

Building your own 18650 battery pack is both satisfying and functional—but it requires caution, skill, and responsibility. Start small with low-current, small-scale packs, follow all safety protocols, and keep learning as you go. With care, you can enjoy reliable performance and tailored energy solutions from your own creations.

-

ICR18650 Battery Explained: Performance, Applications, and Safety Tips

What Is ICR18650 Battery?

The ICR18650 battery is popular cylindrical lithium-ion cell. “ICR” stands for Lithium Cobalt Oxide (LiCoO₂) chemistry used as the cathode material. It follows the standard 18650 dimensions—18mm in diameter and 65mm in length—making it widely used in consumer electronics and compact devices.

Thanks to its high capacity, compact structure, and relatively low cost, the ICR18650 remains a go-to choice for portable electronics. However, compared to other 18650 battery types such as INR and IMR, it offers lower thermal stability and reduced discharge current capability.

Performance Specifications of the ICR18650 Battery

The ICR18650 excels in energy density, offering common capacities such as 2200mAh, 2600mAh, and 3200mAh. For example, the Samsung ICR18650-26F provides a 2600mAh capacity and performs reliably under medium loads.

However, it isn’t suitable for high-drain devices. The typical maximum continuous discharge current is around 2C (4–6A), and the chemistry is sensitive to overcharging and over-discharging. For safety, users should always pair the cell with a Protection Circuit Board (PCB).

Typical Applications of ICR18650 Batteries

Thanks to their large capacity and low cost, ICR18650 batteries work well in:

- LED flashlights

- Small household electronics and toys

- Battery packs with BMS integration

- Low-power portable medical devices

However, avoid using them in power tools, e-scooters, or drones, where high discharge current can lead to overheating and safety risks.

Pros and Cons of ICR18650 Batteries

Advantages:

- High energy density for longer runtime

- Lower cost compared to other lithium chemistries

- Industry-standard size, easy to replace and assemble

Disadvantages:

- Lower safety rating, not suitable for high-heat environments

- Not designed for high-current discharges

- Prone to thermal runaway if overcharged or short-circuited; always use with a protection board

ICR18650 vs Other 18650 Battery Types

Type Chemistry Energy Density Safety Discharge Rate Typical Applications ICR LiCoO₂ ★★★★ ★ ★★ Portable devices, low-drain gadgets IMR LiMn₂O₄ ★★★ ★★★★ ★★★ Power tools, drones INR Li(NiCoMn)O₂ ★★★★ ★★★ ★★★★ E-scooters, power batteries LiFePO₄ LiFePO₄ ★★ ★★★★★ ★★★ Energy storage, medical, EVs Safety Tips for Using ICR18650 Batteries

To ensure safe use of ICR18650 batteries, follow these best practices:

- Always use a protection circuit to prevent overcharging and over-discharging

- Never short-circuit, puncture, or disassemble the battery

- Keep the battery away from heat or direct sunlight

- Check regularly for swelling or leakage

- Store in a cool, dry place with voltage between 3.6V and 3.8V

Is ICR18650 the Right Choice for Your Application?

If your product demands high capacity but low current, such as LED flashlights or compact electronics, the ICR18650 offers a cost-effective and practical solution.

However, if you prioritize greater safety or high discharge performance, you should consider alternatives like INR, IMR, or LiFePO₄.

Choosing the right battery type not only affects product performance but also plays a vital role in ensuring user safety and system stability. -

Understanding 7.4V 18650 Battery Pack Capacities: Selection Guide for OEM Buyers

Why 7.4V 18650 Battery Packs Matter

OEM manufacturers and system integrators rely heavily on 7.4V lithium battery packs built from 18650 cells due to their balance of power, stability, and compact size. But when it comes to selecting the right battery, capacity plays a central role in determining performance and runtime.

This article walks you through common 7.4V 18650 battery capacities and helps you choose the most suitable configuration based on your application requirements.

Common 7.4V 18650 Battery Capacities

A 7.4V lithium battery pack is typically configured as 2S (2 cells in series), with one or more cells in parallel (P) to increase capacity. Below are some of the most common 2S configurations:

Configuration Capacity (Typical) Notes 2S1P (1 cell per series) 2000mAh – 2600mAh Lightweight, compact 2S1P with high-capacity cells 3000mAh – 3500mAh Higher runtime, same size 2S2P 4000mAh – 7000mAh Doubled capacity, slightly larger Custom 2S3P or more 8000mAh+ For high-drain or long-runtime devices Which Capacity Fits Your Application?

Here’s a breakdown of what each capacity range is best suited for:

2000mAh–2600mAh: Compact Electronics & Wearables

- Ideal for lightweight, portable devices

- Examples: handheld medical tools, GPS trackers, LED lighting

- Benefits: small size, low cost, easy integration

3000mAh–3500mAh: Drones & Medium-Power Tools

- Offers more power without increasing battery size

- Examples: camera drones, industrial sensors, e-scooter accessories

- Benefits: extended operation, compact footprint

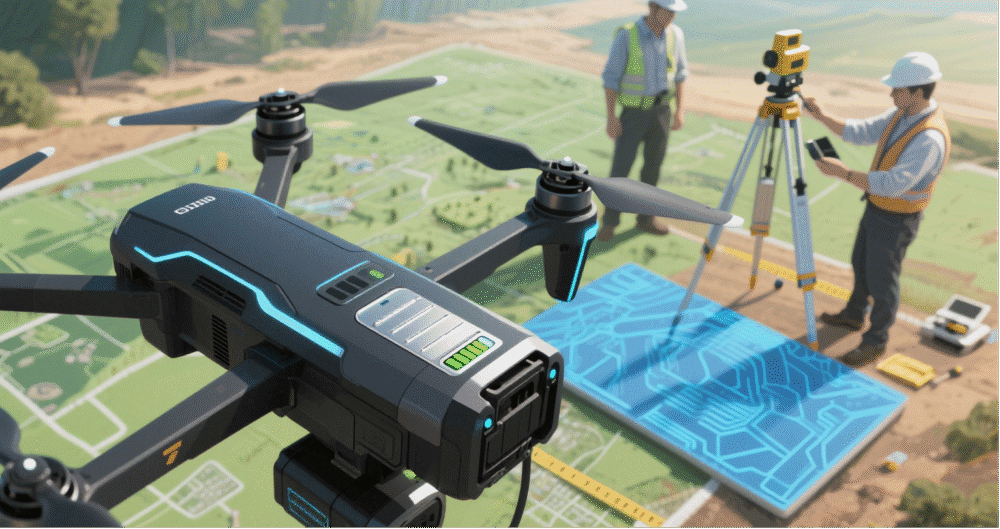

4000mAh–7000mAh (2S2P): High-Drain Equipment

- Perfect for equipment requiring stable, continuous power

- Examples: surveying drones, industrial robotics, wireless POS terminals

- Benefits: increased endurance, excellent heat control

7000mAh and above: Customized Heavy-Duty Applications

- For OEM projects requiring long runtimes or high peak loads

- Examples: agriculture UAVs, mobile workstations, medical carts

- Benefits: tailored design, optimized cell balancing, enhanced BMS options

How to Choose the Right 7.4V Battery Configuration

When selecting a 7.4V 18650 lithium battery pack, consider the following:

- Device voltage requirements: Is 7.4V nominal voltage appropriate?

- Peak and continuous current: Match capacity to discharge rate.

- Battery size constraints: Will a 2S2P or 2S3P pack fit in your device?

- Runtime needs: Longer missions or intermittent use?

- Certification & safety needs: UN38.3, MSDS, UL, IEC62133?

Choosing the right 7.4V 18650 battery pack capacity is a balance between power demand, size, and runtime expectations. Whether you’re building smart electronics or industrial drones, understanding your device’s real needs will help you select the most cost-effective and high-performance battery solution.

If you’re OEM buyer looking for custom 7.4V lithium battery packs, our team can design battery solutions tailored to your project—from 2000mAh to 10,000mAh and beyond.

Need Help Choosing Battery?

Contact us for professional battery pack recommendations, OEM customization, or bulk ordering inquiries. We offer complete technical support and international shipping.

-

What to Consider When Bulk Purchasing 7.4V 18650 Lithium Battery Packs

Cell Quality Determines Core Performance

The quality of lithium cells defines the performance, lifespan, and consistency of a 7.4V battery pack. Manufacturers usually assemble these packs with two 18650 cells in series.

To ensure reliability, buyers should request datasheets, production batch numbers, and test reports for capacity and internal resistance. Avoid packs made from recycled or B-grade cells, which can compromise safety and performance.

Complete Certifications Guarantee Export Compliance

Certifications are mandatory for bulk shipments, especially for export or integration into electronic devices. Reputable suppliers provide essential certifications such as:

- UN38.3 for lithium battery transport safety

- MSDS for chemical safety information

- ROHS/REACH for environmental compliance

- CE/FCC for regional market access

- UL or IEC62133 for high-end or regulated industries

You should verify that certifications match the exact battery pack model. Incomplete or incorrect documentation may delay customs clearance or cause shipment failure.

BMS Configuration Ensures Safe Operation

The Battery Management System (BMS) is essential for protecting a 2S 7.4V lithium pack. It controls voltage, current, and temperature to prevent overcharge, over-discharge, short circuit, and overheating. A standard BMS for a 7.4V pack should include:

- Overcharge protection (usually at 4.25V per cell)

- Over-discharge protection (around 2.5–2.8V per cell)

- Short circuit and overcurrent protection

- Temperature sensor and auto-recovery

- Cell balancing (for high-end or cyclic applications)

If your device requires high reliability—such as drones, robotics, or medical equipment—choose BMS modules with advanced features like I2C communication or fuel gauge monitoring.

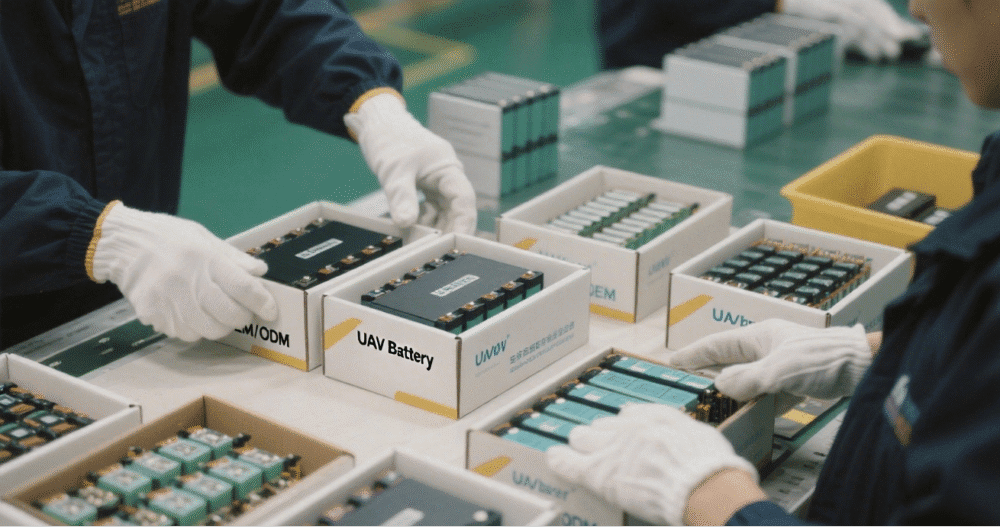

Assembly Workmanship Affects Consistency and Appearance

A well-assembled battery pack ensures stable performance and neat appearance. Professional manufacturers use:

- Pure nickel strips for better conductivity

- Spot welding or laser welding to guarantee firm connections

- PVC wrapping or ABS housings for insulation and protection

- Standardized wiring and connectors, such as JST, XT60, DC plugs

Poorly made battery packs may have inconsistent welds, loose terminals, or exposed wires, which can cause short circuits or mechanical failure. Visual inspections or sample orders can help you evaluate production quality.

Customization Capability Defines Product Compatibility

Different applications require different specs. A reliable battery supplier can offer:

- Custom capacities (e.g., 2000mAh, 2600mAh, 3000mAh, 3500mAh)

- Tailored output current ratings based on peak load

- Flexible structure designs: L-shape, flat, stacked

- Custom wire harnesses and connectors (JST, XT30, bare leads, etc.)

For advanced applications, manufacturers can also integrate waterproof housings, heaters, battery indicators, or communication ports. You should share device dimensions, max load, and battery compartment layout to ensure the best-fit design.

Choose the Right Supplier for Long-Term Success

When purchasing 7.4V 18650 lithium battery packs in bulk, prioritize more than just price. Evaluate the supplier’s ability to deliver high-quality cells, complete certifications, reliable protection systems, and strong customization support. Working with a professional manufacturer reduces your risk, ensures long-term product reliability, and enhances customer satisfaction.

-

OEM 7.4V 18650 Lithium Battery Packs: What Buyers Need to Know

Choosing the right OEM 7.4V 18650 lithium battery pack is crucial for businesses that rely on reliable, long-lasting power sources. Whether you’re designing portable electronics, medical devices, or robotics, selecting a professional OEM partner ensures your battery pack meets both technical and safety standards.

What Is OEM 7.4V 18650 Battery Pack?

OEM (Original Equipment Manufacturer) battery pack is customized by a manufacturer to match the specific requirements of a client’s device or system. A 7.4V configuration usually consists of two 18650 cells in series (2S), delivering stable performance, high energy density, and long cycle life. OEM services go beyond assembly—they include design, BMS integration, casing, labeling, and even certification.

Why Choose OEM Supplier Instead of Ready-Made Packs?

OEM suppliers allow you to control every detail—from battery chemistry and protection circuits to connectors and housing. This ensures compatibility with your device and enhances reliability and safety. For industrial and medical applications, where product failure can be costly or dangerous, OEM customization is often essential.

Key Factors to Evaluate When Choosing an OEM Supplier

When evaluating an OEM lithium battery supplier, consider the following:

- Certification Capabilities: Can they provide CE, UN38.3, UL, RoHS?

- Design Experience: Do they have case studies or projects in your industry?

- Production Scale: Can they handle large orders with consistent quality?

- Technical Support: Do they offer design consultations or BMS solutions?

Selecting an experienced OEM partner can save you time, reduce risk, and improve product reliability.

OEM Case Example: 7.4V Battery for Medical Devices

One example is a 7.4V 2000mAh battery pack customized for a portable medical suction machine. The customer required compact size, overcurrent protection, and medical-grade certification. The OEM partner designed a 2S1P pack with protective BMS, flame-retardant casing, and passed UN38.3 and IEC62133 tests.

Conclusion

OEM 7.4V 18650 lithium battery packs offer flexibility, performance, and safety for custom-powered devices. Working with the right supplier ensures that your batteries meet the exact demands of your application, reducing development cycles and improving end-user satisfaction.

-

Top 5 Long-Endurance Drone Batteries for Industrial Applications in 2025

As industrial drone applications continue to expand, long flight endurance has become a key concern for users across various sectors. Whether for agricultural spraying, power line inspections, geospatial mapping, or emergency response, a high-performance, long-endurance drone battery directly impacts operational efficiency and flight stability.

This article recommends five high-performing long-endurance industrial drone batteries in 2025, evaluated across capacity, cell technology, and application scenarios. It also offers selection and customization tips for B2B procurement.

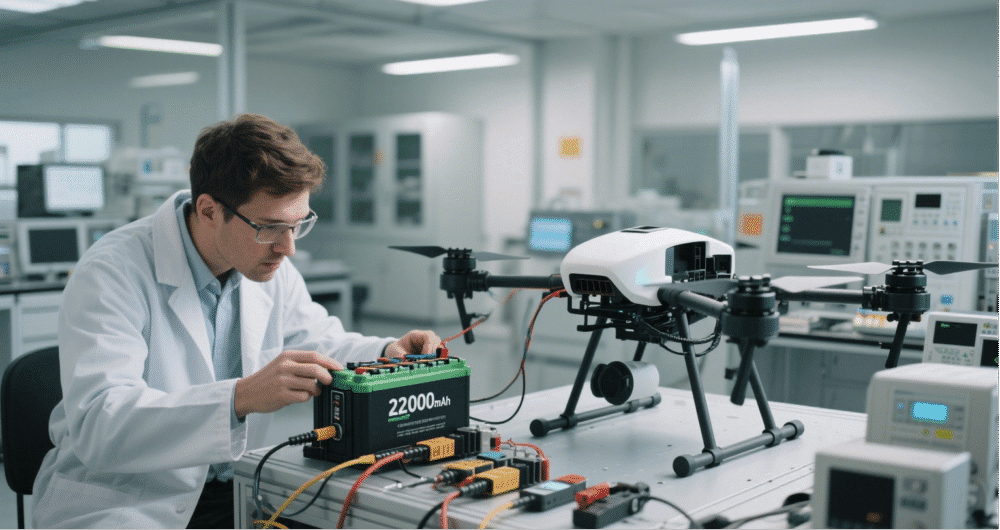

1.22.2V 22000mAh High Discharge Rate LiPo Battery – Built for Agricultural Drones

- Capacity: 22000mAh

- Voltage: 6S (22.2V)

- Ideal For: 6-axis to 8-axis crop spraying drones

- Discharge Rate: 15C

- Flight Time: 30–45 minutes

This battery uses high energy-density lithium polymer (LiPo) cells and supports high-current discharge, making it perfect for heavy-duty agricultural drones. It features a built-in high-performance BMS for overvoltage, overcurrent, and short-circuit protection.

2.44.4V 12000mAh High-Voltage Li-ion Battery – Custom-Made for Power Inspection Drones

- Capacity: 12000mAh

- Voltage: 12S (44.4V)

- Highlight: High voltage platform, lower energy loss

- Application: Power line inspection, substation monitoring

The high-voltage configuration enhances motor efficiency and reduces energy loss, making it ideal for large-area, long-range inspection missions. Optional GNSS modules support high-altitude operations under complex weather conditions, enabling all-weather deployment.

3.29.6V 16000mAh Smart UAV Battery – For Mapping and Urban Logistics

- Capacity: 16000mAh

- Voltage: 8S (29.6V)

- Key Features: Smart BMS + Bluetooth telemetry

- Applications: Surveying drones, delivery drones

This lightweight battery features real-time power feedback and health monitoring. It’s widely used in mapping UAVs and low-altitude urban delivery systems. It provides over 40 minutes of flight time, supporting multi-mission operations.

4.Custom 6S–12S UAV Battery Modules – Preferred by OEM Clients

- Available Capacity: 10000–30000mAh

- Custom Voltage Options: 22.2V / 29.6V / 44.4V

- Form Factor: Hard case / Soft pack / IP66 Waterproof

- Designed For: OEM/ODM drone manufacturers

We support full customization including appearance, connectors, voltage, and certifications. These battery packs meet UN38.3, MSDS, CE, and RoHS standards, making them export-ready and ideal for clients with personalized demands.

5.LiFePO4 Long-Life Drone Battery – Safe and Reliable for Education and Security Patrols

- Voltage: 22.4V (7S)

- Capacity: 12000mAh

- Cycle Life: ≥2000 cycles

- Safety Features: High temperature resistance, fireproof, chemically stable

Although slightly larger than LiPo batteries, this LiFePO4 battery suits low-risk applications requiring long service life and frequent cycling, such as campus education drones or routine security patrol UAVs.

How to Choose the Right Long-Endurance Drone Battery?

For wholesale buyers, consider the following factors when selecting a long-endurance UAV battery:

- Voltage & Capacity Compatibility: Ensure it matches with flight controllers, motors, and propellers

- Application Scenario: High payload operations (e.g., agriculture, logistics) require higher discharge rates

- Weight-to-Energy Ratio: Heavily affects flight time

- Cycle Life vs. Cost Efficiency: Impacts total cost of ownership (TCO)

- Compliance & Certification: Ensure batteries meet target market regulations

Bulk Purchasing & Customization Services

We offer OEM/ODM services, including logo printing, small batch prototyping, and full certification for transportation (UN38.3, air freight packaging, etc.). Contact us to get detailed specifications and explore long-term supply options.

-

How to Store eBike Battery Properly? A Must-Read Guide for Wholesalers

Why Proper eBike Battery Storage Matters

eBike batteries, typically lithium-ion, are highly sensitive to environmental conditions such as temperature, humidity, and charge level. For wholesalers managing large inventories, improper storage can lead to serious issues—capacity degradation, swelling, leakage, and even safety hazards.

Five Key Storage Tips for Battery Wholesalers

1. Control Temperature and Humidity

Maintain a stable storage temperature between 15°C and 25°C, with relative humidity between 45% and 75%. Drastic temperature fluctuations or high humidity can severely impact battery life and safety.- Use dehumidifiers and temperature control systems

- High heat may cause swelling or accelerate chemical reactions

2. Store Batteries with a Partial Charge

Keep battery charge between 30% and 60% during storage. Fully discharged or fully charged batteries are prone to degradation.- Check voltage every 3 months and recharge if necessary

- Use a Battery Management System (BMS) to monitor health

Battery Transport and Labeling Requirements

For cross-border wholesalers and exporters, compliance with transport regulations is critical. Follow IATA Dangerous Goods guidelines when exporting.

- Categorize batteries before storage: new, used, and pending inspection

- Label each package clearly (e.g., UN3480 / UN3481)

4Common Storage Mistakes and How to Avoid Them

Common Mistake Potential Risk Best Practice Stacked storage with poor ventilation Overheating, deformation Use shelving with gaps and ensure airflow Infrequent voltage checks Over-discharge and failure Test and recharge batteries every 3 months Storing in non-specialized warehouses Moisture, static hazards Choose facilities with moisture and static control

Develop a Battery Storage SOP for Bulk Orders

To standardize inventory management, wholesalers should establish a Battery Storage Standard Operating Procedure (SOP). Key components include:

- Temperature and humidity control guidelines

- Regular inspection schedules

- Classification and labeling rules

- Pre-shipment performance testing procedures

Conclusion

For eBike battery wholesalers, proper storage directly affects product quality, warranty claims, and customer satisfaction. By managing environmental conditions, charge levels, transport safety, and routine maintenance, you can minimize loss and maximize inventory value.

-

5 Things You Must Know About Bulk Purchasing 18650 Lithium Batteries

1. What Is the MOQ for 18650 Batteries and Why Does It Matter?

In bulk procurement, MOQ (Minimum Order Quantity) refers to the smallest number of units a manufacturer requires to begin production and packaging. It ensures that production costs and profit margins are covered.

Typical MOQ ranges:

- Standard unprotected cells: MOQ 1,000–5,000 units

- 18650 batteries with PCB protection: MOQ 500 units

- Custom battery packs (e.g., 2S1P, 3S2P): MOQ 100–300 packs

Understanding the MOQ helps you plan purchase volumes more efficiently and negotiate better terms.

2. 6 Key Factors That Affect 18650 Battery Wholesale Pricing

The unit price for 18650 batteries varies based on these core factors:

- Battery capacity: 3000mAh models typically cost 20–40% more than 2000mAh

- Protection circuit: Adding PCB increases cost by $0.10–$0.30 per unit

- Custom packaging or labeling: OEM/ODM services may add $0.10–$0.20 per unit

- Order quantity: Bulk discounts often apply for orders over 5,000 units

- Shipping and certifications: Batteries with UN38.3, MSDS, or air freight clearance may have higher base prices

Knowing these variables helps you evaluate if a quote is reasonable.

3. How to Negotiate Better Wholesale Pricing with Manufacturers

To secure more competitive pricing, effective communication with your supplier is key. Here’s how you can improve your negotiating power:

- Share your monthly or quarterly purchase plans to request long-term pricing

- Explain product application so the supplier can recommend the most cost-effective battery

- Ask if there are discounts for in-stock models or mixed batches

- Confirm if partial shipments and flexible invoicing are available

- Discuss shipping methods and customs clearance upfront to avoid hidden costs

Being transparent and professional often leads to better deals.

4. Recommended Bulk Purchase Solutions by Application Scenario

Paragraph keyword: battery application scenarios, custom 18650 battery, industry-specific battery solutions

Different industries have unique requirements when sourcing 18650 batteries:

- LED flashlight manufacturers: Prefer 2600mAh+ batteries with protection for safety

- Power tools brands: Need high-discharge customized packs like 3S2P or 4S1P

- Medical device suppliers: Should prioritize batteries with MSDS & UN38.3 for international shipping

- Amazon sellers: Focus on customizable labels and branding-friendly packaging

Matching product specs with usage scenarios improves long-term satisfaction and safety.

5. How to Identify a Reliable 18650 Battery Wholesale Supplier

A trustworthy battery supplier should meet the following criteria:

- Holds certifications like ISO9001, CE, UN38.3, and MSDS

- Offers free samples or trial orders for testing

- Has in-house cell testing and pack assembly lines

- Supports OEM/ODM customization and engineering collaboration

- Guarantees fast delivery: 7–15 working days

Working with a certified supplier ensures product safety, compliance, and smoother transactions.

Conclusion

Buying 18650 batteries in bulk isn’t just about chasing the lowest price. You need to consider MOQ, certifications, delivery time, and product safety to make the right choice. This guide aims to help you source smarter, save costs, and build long-term supplier relationships.

-

10 Frequently Asked Questions You Must Know Before Customizing UAV Battery Packs

1. What is the Minimum Order Quantity (MOQ) for Custom UAV Battery Packs?

Most manufacturers have a MOQ of 50 to 100 units. However, some offer sample customization to facilitate early testing.

2. What Voltages and Capacities Can Be Customized?

Common customizable specifications include:

- Voltage: 7.4V / 11.1V / 14.8V / 22.2V / 29.6V (2S~8S Li-ion batteries)

- Capacity: Ranges from 2000mAh to 30000mAh, designed based on flight duration requirements

- Cell Types: Soft pack / 18650 cylindrical / high-power lithium cells

How to Estimate the Required Battery Capacity?

Use the formula:Required Capacity (mAh) = Total Power × Flight Time / Voltage × 1000

We recommend providing:- Expected flight time

- Flight controller system power consumption

- Motor specifications

We will help calculate precisely and recommend the proper cells.

3. What BMS Protection Features Are Available?

All custom battery packs can be equipped with a Battery Management System (BMS). Common protection functions include:

- Overcharge / Over-discharge / Short-circuit / Overcurrent protection

- Cell balancing

- Temperature monitoring

- Communication protocol support (SMBus, I2C, CAN)

4. Do the Batteries Support Fast Charging or Smart Communication?

Yes. Some battery cells support 3C~5C fast charging. We can also integrate smart BMS modules (e.g., I2C, UART) that connect seamlessly with flight control systems to provide real-time data such as battery level, voltage, and temperature.

5. Do the Batteries Meet International Transport and Export Certifications?

Our battery products support the following certifications:

- UN38.3 for air transport

- MSDS and IEC62133

- ROHS / CE (upon request)

We also provide DG labels and complete export documentation.

6. What is the Battery Lifespan and Charge Cycle Count?

High-quality lithium cells typically support 300–800 charge-discharge cycles. The actual lifespan depends on usage scenarios, current rate, and temperature control. Under proper conditions, custom batteries can operate for 2–3 years.

7. What Is the Customization Lead Time?

Typical delivery timeline:

- Solution confirmation: 1–3 days

- Sample production: 5–7 days

- Mass production: 10–15 days

If a special structure or mold is needed, the timeline may be extended.

8. What Structural Options Are Supported? Are They Waterproof or Shockproof?

We offer structural customization based on application environments, including:

- ABS or PC+Glass fiber enclosures

- Waterproof potting

- Shock-absorbing foam support

- IP65–IP67 protection levels

Suitable for outdoor, cold, or high-humidity environments.

9. How Can I Start the Customization Process?

Simply provide the following:

- Target voltage and capacity

- Size constraints (if any)

- Application type and power consumption

- Any required certifications, waterproofing, communication features

You can submit your requirements via email or online form, and we will respond promptly.

Conclusion

Custom UAV battery packs play a crucial role in enhancing UAV system performance. This article has clarified the top 10 frequently asked questions to help you better understand the purchasing and customization process. If you have specific needs, feel free to contact our technical team. We’ll provide a one-on-one custom solution tailored to your project.

-

How to Choose the Right Custom UAV Battery Packs for Your Drone Fleet

Why Custom Battery Packs Matter for UAVs

In industrial drone applications—such as agricultural spraying, security inspection, aerial mapping, and logistics—flight time, payload capacity, and safety requirements are much higher. Off-the-shelf battery packs often fall short due to mismatched dimensions or voltages, leading to performance issues or even mission failure.

Cell Types and Discharge Rates (C-Rating)

Common battery cell types include:

- Li-ion (Lithium-ion): High energy density, ideal for long-duration flights

- LiPo (Lithium Polymer): Lightweight structure, supports high current bursts

- LiFePO4 (Lithium Iron Phosphate): Excellent safety and long cycle life, perfect for high-frequency flight missions

The discharge rate (C-rating) determines whether the battery can handle peak current during takeoff, climbing, or carrying payloads. It’s important to match this with the drone’s maximum current draw.

Voltage, Capacity, and Mission Requirements

- Voltage: Should match the motor and flight controller specs—common options include 11.1V (3S), 14.8V (4S), and 22.2V (6S).

- Capacity (Ah): Directly affects flight time. Agricultural spraying drones usually require 8000mAh or more, while mapping drones prioritize lightweight design.

- Dimensions: Must be precisely tailored to the drone’s battery compartment to avoid fit issues or shaking during flight.

Tip: We offer custom configurations from 7.4V (2S to 12S series/parallel combinations), and support XT60, XT90, AS150, and aviation-grade connectors.

Smart BMS and Safety Protection

High-performance drones require intelligent battery management systems:

- Real-time monitoring of charge level, voltage, and temperature

- Protection against overcharge, over-discharge, overcurrent, and short circuit

- Communication protocols like SMBus, CAN, and UART for seamless integration with flight controllers

Safety Tip: Custom battery packs must comply with certifications such as UN38.3, MSDS, and IEC62133 to ensure air/sea shipping compliance.

Bulk Purchasing and Customization Process

What do bulk buyers care about most?

- Minimum Order Quantity (MOQ): Flexible options available (e.g., from 5–10 pieces)

- Customization Lead Time: Sample in 3 days, mass production in 7 days

- OEM/ODM Support: Logo printing, custom mold production available

- Certifications: UN38.3 / MSDS / UL / CE documents can be provided

Suggestion: Share your full requirement checklist with the battery manufacturer—including dimension diagrams, working voltage, continuous current, connector types—to accelerate prototyping.

Conclusion: Choosing a Professional UAV Battery Manufacturer Is Key

A reliable custom UAV battery supplier doesn’t just deliver well-matched products—they ensure flight stability and long-term performance for your drone systems. They also help streamline OEM production and bulk procurement.

If you’re looking for high-performance, fast-delivery custom UAV battery packs, feel free to contact us for a tailored quote and expert technical support.