If you’re sourcing lipo battery for UAV in bulk, you probably already know one thing:

on paper, most batteries look “good enough.”

Same voltage. Similar capacity. Discharge rate looks impressive.

But once those packs go into real UAV platforms… things start to feel different.

And honestly, that’s where most wholesale decisions either make sense — or quietly turn into long-term problems.

I’ve seen this play out more than once.

Why “Lipo Battery for UAV” Is Not a Single Product Category

This is something people don’t like to admit at first.

A lipo battery for UAV used in mapping drones behaves very differently from one used in long-range inspection or heavy-lift logistics.

Same chemistry, sure. Totally different stress profile.

Some UAVs want:

- stable voltage over long hover time

- low internal resistance at partial load

Others are all about:

- short bursts

- aggressive current draw

- fast climb, fast drop

So when wholesalers ask, “What’s your best lipo battery for UAV?”

I usually pause.

Best… for which flight profile?

That question alone filters out a lot of bad sourcing decisions.

Capacity Numbers Look Nice. Flight Time Tells the Truth.

Let’s talk about capacity for a second.

On spec sheets, 6S 16000mAh and 6S 22000mAh look like a clear upgrade path.

In the air? Not always.

Higher capacity means:

- more weight

- higher inertia

- different motor efficiency curve

I didn’t expect this at first, but in several UAV builds, a slightly smaller lipo pack delivered more usable flight time simply because the drone wasn’t fighting its own mass.

This is exactly why understanding lipo battery for UAV performance under real load matters more than chasing big numbers.

If you want a deeper breakdown of how lipo batteries behave specifically in drone applications, check out this article on Lipo Battery for Drone Power Systems

explains the internal logic really well, especially around discharge behavior and thermal response.

Discharge Rate: The Most Misunderstood Part (Even by Buyers)

C-rating is probably the most abused parameter in UAV battery sourcing.

High C doesn’t mean better.

It means capable — if the rest of the system actually demands it.

For wholesale UAV projects, overspec’ing discharge rate often leads to:

- unnecessary cost

- thicker tabs

- stiffer cells with lower energy density

And under-spec’ing it? That’s worse.

Voltage sag, heat buildup, unstable flight control — all things operators notice immediately.

When sourcing lipo battery for UAV wholesale, the real question isn’t “What’s the max C?”

It’s “What’s the continuous C under sustained UAV load?”

That’s where real manufacturing experience shows.

Why More Buyers Are Moving Toward Specialized UAV Battery Packs

Here’s a quiet trend you’ve probably noticed.

More buyers are no longer asking for “generic lipo packs.”

They’re asking for:

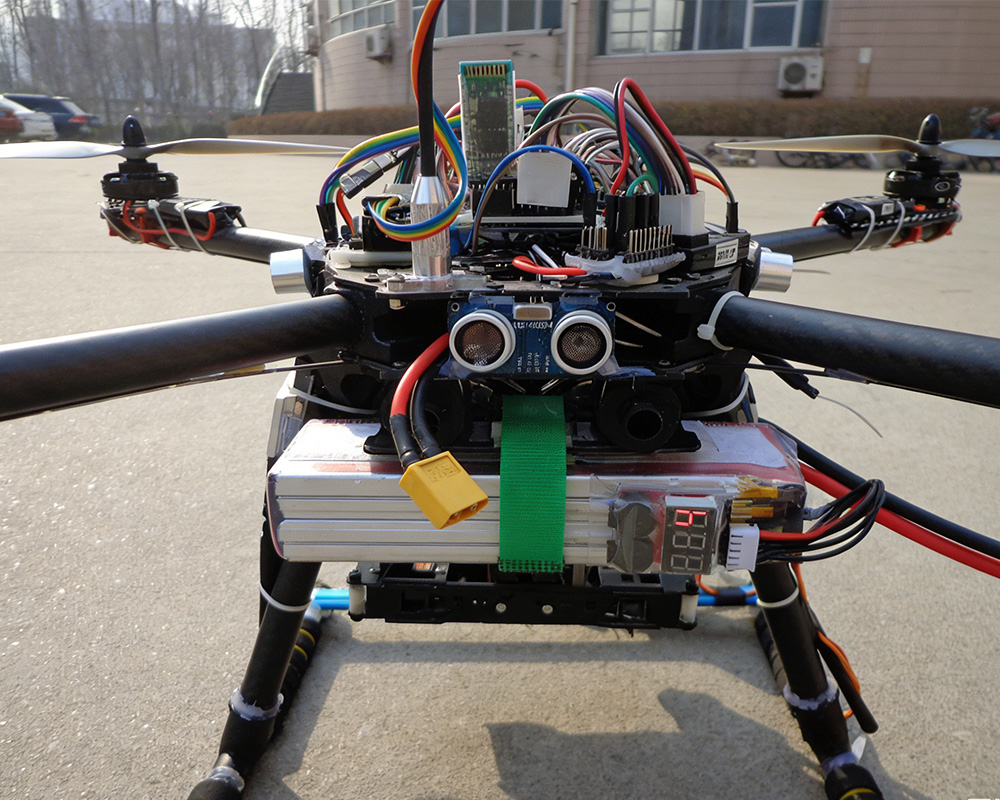

- UAV-specific form factors

- reinforced balance leads

- vibration-resistant internal structure

Because UAVs don’t fail like RC toys.

They fail mid-air. Over people. Over assets.

That’s why many wholesale buyers now prefer sourcing from suppliers that focus specifically on UAV battery categories, not just lithium cells in general.

If you’re evaluating different configurations and use cases, it’s worth browsing a dedicated UAV Battery Product Category

instead of mixing drone packs with unrelated lithium products.

You’ll immediately see differences in structure, connector logic, and pack design philosophy.

Consistency Beats Peak Performance (Especially for Wholesale Orders)

Here’s something that doesn’t show up on spec sheets.

Batch consistency.

In UAV projects, one unstable batch can destroy:

- a flight test schedule

- an integration timeline

- or worse, client trust

For wholesale buyers, I’d take:

- slightly lower peak performance

- over unpredictable cell behavior

…any day.

That’s why experienced buyers tend to care more about:

- cell matching process

- internal resistance spread

- aging curve stability

Not glamorous topics. But extremely practical ones.

What Actually Converts End Clients

At the end of the day, your customer doesn’t care how good the battery sounds.

They care whether the UAV:

- flies as expected

- repeats missions reliably

- doesn’t surprise them in the worst moment

A well-matched lipo battery for UAV becomes invisible.

And that’s the best compliment it can get.

If your supplier understands UAV use cases — not just lithium chemistry — you’ll feel it after the first few shipments.

Final Thought

If you’re buying lipo battery for UAV in volume, don’t think like a spec hunter.

Think like someone who has to answer emails after deployment.

That mindset alone changes:

- how you evaluate samples

- how you read datasheets

- and who you trust as a long-term supplier

And yes — it usually leads to better inquiries, not more problems.

Leave a Reply