Your cart is currently empty!

Category: Battery FAQ

-

Lithium Ion Battery vs LiPo,How Should You Actually Choose?

Many people still get confused about lithium ion battery vs LiPo.

To be honest, the two have been debated in the battery world for more than a decade.Some say LiPo is a completely different chemistry.

Some say LiPo is just a variation of Li-ion.

Others insist there’s “no real difference” besides the packaging.But the moment you actually use these batteries, test them, or tear them apart, things get clearer.

They are not identical, and they are not totally different either.

The truth sits somewhere in the middle.This guide explains everything in simple, practical language — no textbook tone, no meaningless theory.

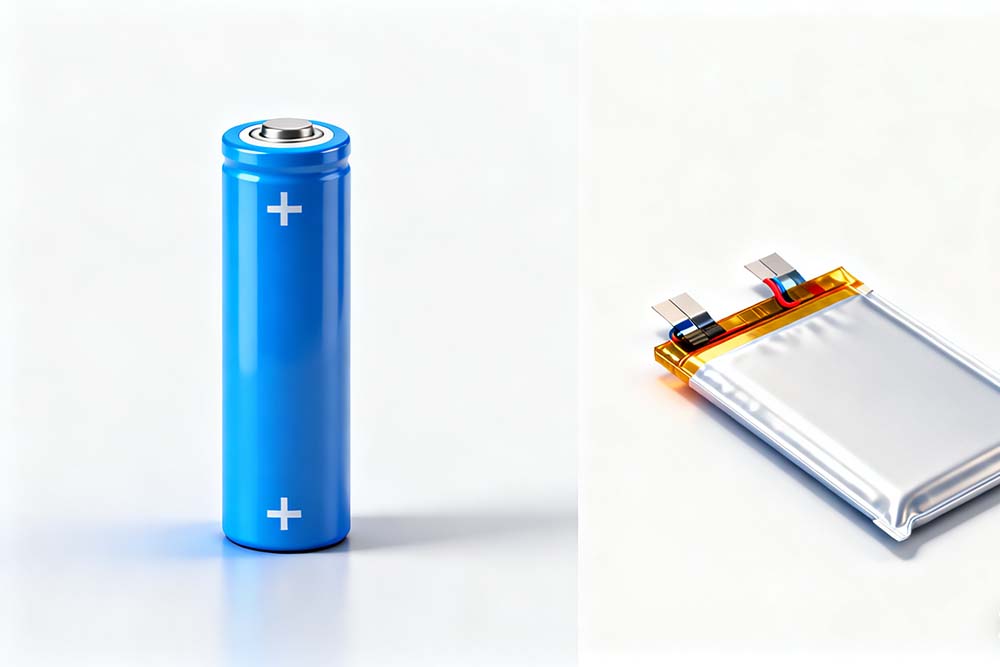

1. LiPo Is Not a New Chemistry — It’s Still Part of the Li-ion Family

Let’s start with the biggest misconception.

LiPo is not a brand-new chemistry.

It belongs to the same lithium-ion family.- Li-ion = big category

- LiPo (lithium polymer) = soft-pouch structure + different electrolyte process

So yes, the chemistry is still lithium-ion.

What actually changes is:- the structure

- the production method

- the way the cell behaves

That’s why the real difference between lithium ion and LiPo is not chemical.

It’s mostly physical and performance-related.2. Structure Is the Biggest Real Difference

This part shapes everything else.

Li-ion: Hard Shell (Metal Case)

Examples include:

- 18650 cells

- 21700 cells

- Aluminum square cells

Key traits:

- strong

- resistant to impact

- resistant to squeezing

- stable, mature manufacturing

LiPo: Soft Pouch (Aluminum-Laminated Film)

Press the pouch and you’ll feel it flex.

Traits:

- lightweight

- thin

- fully customizable shapes

- but sensitive to pressure, bending, and piercing

In simple terms:

Li-ion feels like a metal can.

LiPo feels like a foil pouch.This structural difference sets the tone for discharge behavior, lifespan, and safety.

3. Discharge Performance — LiPo Wins on Pure Power

When it comes to high output, LiPo takes the lead.

LiPo: Built for High Current

High discharge rates like 30C or 50C are common.

Great for:

- FPV drones

- RC cars

- devices that need instant bursts of power

- aggressive acceleration loads

Li-ion: Built for Endurance

Li-ion cells focus on stable, long-lasting output.

They don’t like high current spikes.Best for:

- long-endurance drones

- power tools

- portable electronics

- energy storage systems

Summary:

LiPo is about power.

Li-ion is about endurance.4. Lifespan — Li-ion Usually Lasts Longer

This is widely known in the industry.

LiPo cells degrade faster, especially under high discharge rates.

Swelling after dozens or hundreds of cycles is totally normal.Li-ion behaves more consistently:

- longer cycle life

- fewer swelling issues

- slower aging

- stronger casing protects the structure

LiPo isn’t “bad.”

It’s just tuned for performance, not longevity.5. Safety — Hard Shell Makes Li-ion More Robust

Safety is another area where structure matters.

Li-ion Safety Advantages

- metal casing

- higher resistance to impact

- better deformation protection

LiPo Safety Weak Points

- soft pouch

- vulnerable to puncture

- sensitive to squeezing and bending

This is why many industrial, medical, and energy storage products prefer Li-ion.

6. How to Choose? Focus on Your Application, Not the Name

Forget the idea of “which one is better.”

A better question is:What does your device actually need?

Choose Li-ion if you need:

- longer lifespan

- stable output

- higher safety

- better endurance

Suitable for:

- long-flight drones

- tools and equipment

- power banks

- UPS and storage

- industrial devices

Li-ion is a reliable, stable, long-distance runner.

Choose LiPo if you need:

- light weight

- thin profile

- flexible size

- high burst current

Suitable for:

- FPV racers

- RC cars

- wearables

- custom industrial designs

- devices with limited or odd-shaped space

LiPo is the choice when you need power and flexibility.

Final Summary

Li-ion = stable, durable, higher energy density

LiPo = lightweight, flexible shape, powerful burstsThey’re not competitors.

They’re tools for different jobs. -

Can You Use 14500 Batteries in Any Flashlight? Here’s the Real Story

If you’ve ever held a 14500 lithium-ion battery in your hand, you might have thought, “Hey, it’s about the same size as a regular AA—why not just swap it in?” Sounds simple, right? Well, not exactly. While 14500 batteries look a lot like AA batteries on the outside, their “inner personality” is totally different. Swap them blindly, and your flashlight might not be happy—sometimes it can even get damaged.

Looks Can Be Deceiving

At first glance, 14500 and AA batteries are almost the same size, so it’s tempting to just pop one in. But here’s the catch: the voltage is way higher. Imagine replacing a standard light bulb with a powerful industrial spotlight—sure, it might shine brighter, but the bulb (and the socket) could fry.

That’s exactly what happens if you put 14500 battery in a flashlight designed only for 1.5V AA cells. It might work for a moment, but over time, the electronics can’t handle it and could fail.

Which Flashlights Can Handle 14500?

Not every flashlight can handle a 14500 battery. Some modern flashlights are designed as “dual fuel,” meaning they can run on either AA batteries or 14500s. These lights are built to safely handle the higher voltage, letting you enjoy brighter output without frying the circuitry.

Before you swap batteries, always check the manual or manufacturer’s specifications. If you’re unsure, online flashlight forums like BudgetLightForum can be a goldmine—other users often share real-life experiences and warnings.

Tips for Using 14500 Safely

- Prioritize safety: Choose protected 14500 batteries—they come with safeguards against overcharging, over-discharging, and short circuits.

- Charge wisely: Don’t use a standard AA charger. Use a charger made for lithium-ion batteries to avoid accidents.

- Check compatibility first: If you’re not 100% sure your flashlight supports 14500, don’t risk it.

Bottom Line

14500 batteries aren’t a one-size-fits-all upgrade. In the right flashlight, they can deliver extra brightness and longer runtime, but in the wrong one, they can cause trouble. The safest approach? Make sure your flashlight can handle 14500s, then pick a quality protected battery. That way, you get the boost without the stress.

-

18650 Button Top Battery: Everything You Should Know

If you’ve ever used a flashlight, power tool, vape, or built your own DIY battery pack, you’ve probably heard of 18650 batteries.

When browsing online, you might notice two common versions — button top and flat top. At first glance, they look nearly identical, but that tiny difference at the top actually matters quite a lot.So, what exactly is an 18650 button top battery, how is it different from a flat top one, and which type should you buy? Let’s break it down in simple terms.

1. What Does “18650” Mean?

“18650” isn’t a model number — it’s a size code.

It simply means:- 18 mm in diameter

- 65 mm in length

- The “0” at the end indicates a cylindrical shape

Because of their high energy density and long lifespan, 18650 lithium batteries have become a universal power source — used in laptops, e-bikes, drones, flashlights, power banks, and even small solar storage systems.

2. What Is a Button Top Battery?

A button top 18650 battery has a small raised “button” on its positive end.

This little bump isn’t decorative — it’s there to make better contact with devices that have deeper battery compartments or flat contact plates.Some devices (like flashlights or older electronics) may not work properly with flat top batteries because the positive end doesn’t quite reach the contact point.

In that case, the extra millimeter or two from a button top makes all the difference.3. Button Top vs Flat Top: What’s the Difference?

Feature Button Top Flat Top Positive End Has a small raised button Completely flat Length Slightly longer (by 1–2 mm) Standard length Contact Better connection with certain devices Might not reach contact points in some designs Best For Flashlights, tools, standalone devices Battery packs, DIY assembly, BMS systems Main Advantage Easy to install and remove Compact and ideal for welding or stacking In short: Button tops are for single-cell use; flat tops are for battery packs.

4. Why Some Devices Require a Button Top

Not every product is designed the same.

Some battery compartments include a protective ring around the positive contact to prevent reverse polarity. That means a flat battery might not touch the terminal at all — and your device simply won’t turn on.A button top fixes that by providing a taller contact point.

Also, devices with loose springs or deeper chambers tend to perform more reliably with button top batteries. On the flip side, ultra-compact designs that leave no space to spare may only fit flat tops.

5. Is There a Performance Difference?

Not really.

The shape of the top doesn’t affect the performance — the chemistry and quality of the cell inside do.Both button top and flat top 18650s can have the same capacity, discharge rate, and lifespan if made from the same grade of lithium cell.

The only small difference is that button tops are often welded on afterward. Poorly made welds could add a tiny bit of resistance, but for normal use, it’s negligible.

6. Practical Tips When Using Button Top Batteries

- Check your device requirements.

If the manual says “button top only,” don’t risk using a flat top — it might not make contact. - Use the same type in pairs or sets.

When your device takes two or more batteries, make sure they’re the same type and length. Mixing button and flat tops can cause poor contact or uneven pressure. - Store and transport safely.

Because the raised end is more exposed, a button top battery is slightly more prone to shorting if it touches metal objects. Always use a plastic case or insulation sleeve when carrying them. - Avoid DIY modifications.

Some people stick magnets or metal shims on flat tops to “fake” a button top — this can fall off and short-circuit your device. Only do this if you absolutely know what you’re doing.

7. Quick Summary

- “18650” refers to the size, not a brand.

- “Button top” is just a contact design for better compatibility.

- There’s no power advantage between button and flat top versions.

- Always check your device specs before buying.

If you’re buying batteries for flashlights, tools, or plug-and-play devices — go with button tops.

If you’re building a custom pack or need to spot-weld connections — use flat tops instead. -

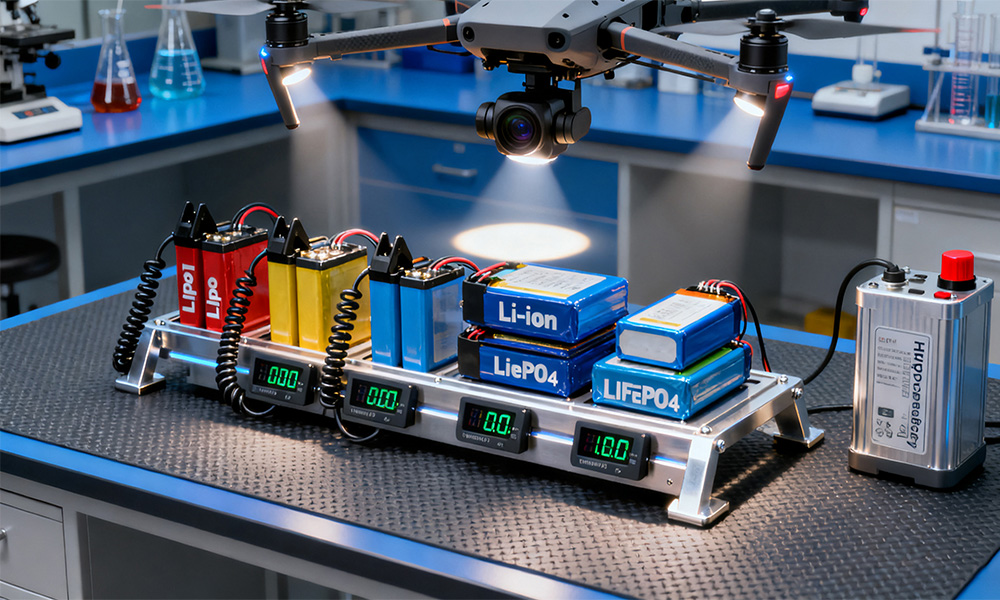

FAQ: What Types of Batteries Are Used in UAVs?

1. What kinds of batteries do drones actually use?

Most UAVs (Unmanned Aerial Vehicles) run on Lithium Polymer (LiPo), Lithium-ion (Li-ion), or Lithium Iron Phosphate (LiFePO4) batteries. Some older or basic models may still use Nickel Metal Hydride (NiMH), but it’s becoming rare. The choice really depends on what the drone is built to do—speed, endurance, or stability.

2. Why are LiPo batteries everywhere in drones?

Because they hit the sweet spot between weight, power, and flexibility. LiPo packs are light and can deliver quick bursts of current, which is exactly what multi-rotor drones need for takeoff and maneuvering. You’ll find LiPo batteries in most consumer and racing drones.

The downside? They’re a bit temperamental—if you overcharge, puncture, or store them wrong, they can swell or overheat. So most UAV operators keep them under strict charging and storage routines.3. How are Li-ion batteries different from LiPo ones?

Li-ion batteries last longer and hold more energy for their size. That means longer flights—but at a lower discharge rate. So, instead of racing drones, you’ll see Li-ion packs in survey, mapping, or fixed-wing UAVs that cruise for 1–2 hours. They’re also safer to handle and more durable across many charge cycles.

4. What’s the deal with LiFePO4 batteries?

These are the workhorses of the UAV battery world. LiFePO4 (Lithium Iron Phosphate) batteries don’t have the same energy density as LiPo or Li-ion, but they’re rock-solid in terms of safety and thermal stability. They can handle heat, rough conditions, and hundreds of cycles. That’s why they’re often used in industrial, agricultural, or military UAVs, where reliability matters more than long flight times.

5. Do any drones still use NiMH or lead-acid batteries?

Only the old-school or budget ones. NiMH and lead-acid batteries are heavy and inefficient compared to lithium-based types. You might find them in training drones, educational kits, or ground control systems, but not in modern UAVs meant for real work.

6. How much does battery choice affect flight performance?

A lot. The type of battery decides how far, how long, and how stable your UAV flies.

- LiPo: best for powerful takeoffs and fast maneuvers.

- Li-ion: ideal for long missions where energy efficiency is key.

- LiFePO4: perfect for harsh environments or long-term reliability.

In short, your battery isn’t just a power source—it’s part of the flight design.

7. Any new battery tech coming for UAVs?

Yes, and fast. Manufacturers are experimenting with high-voltage LiPos, graphene-enhanced cells, and solid-state lithium batteries that could double flight time and safety. For larger UAVs, hydrogen fuel cells and hybrid battery systems are also being tested to push endurance even further.

8. How can drone operators make their batteries last longer?

A few small habits go a long way:

- Don’t overcharge or fully drain the pack.

- Store batteries at around 50–60% charge when idle.

- Avoid extreme temperatures.

- Use a balancing charger to keep all cells equal.

Handled right, a good UAV battery can easily last over 300–400 charge cycles before noticeable drop-off.

Summary:

In today’s UAV market, LiPo and Li-ion batteries dominate because they strike the best balance between performance and weight. LiFePO4 is the go-to for industrial applications where safety and cycle life matter more. As battery tech keeps evolving, we’re getting closer to drones that can stay in the air for hours instead of minutes.

-

Custom Ebike Battery FAQ

Electric bikes are everywhere these days, but the real headache for most riders isn’t the bike itself — it’s the battery. Maybe you bought a stock battery and realized it no longer meets your needs after a year, or you’ve run out of juice mid-ride and had to push your bike home. That’s why many riders are searching for custom ebike batteries.

Below, we’ll walk through the most common questions about custom electric bike batteries, explained in plain language.

1. What is a Custom Ebike Battery?

In short, it’s a battery built specifically for your needs.

Unlike generic factory packs, a custom ebike battery is designed around your frame, riding style, and energy demands. It could be long and slim, triangular, or even curved to fit into unusual spaces. Voltage and capacity are tailored to match your motor and controller, not just an off-the-shelf spec.

Think of it like clothing: some people wear “one-size-fits-all,” but if you go to a tailor, the fit is on another level.

2. Why Choose a Custom Ebike Battery?

Most people immediately think of “longer range,” but there are more reasons:

- Extended range: If your commute is 40 km but the standard battery only covers 25, you’re constantly worried. A custom pack can double the capacity.

- Stronger performance: After upgrading to a powerful motor, the stock battery often can’t deliver the current needed. A custom pack unlocks the motor’s full potential.

- Better space use: Folding frames and odd-sized bikes often can’t house factory batteries. Custom packs can be shaped to fit perfectly.

- Durability: With high-grade cells and a quality BMS (Battery Management System), lifespan can stretch from 2 years to 5+ years.

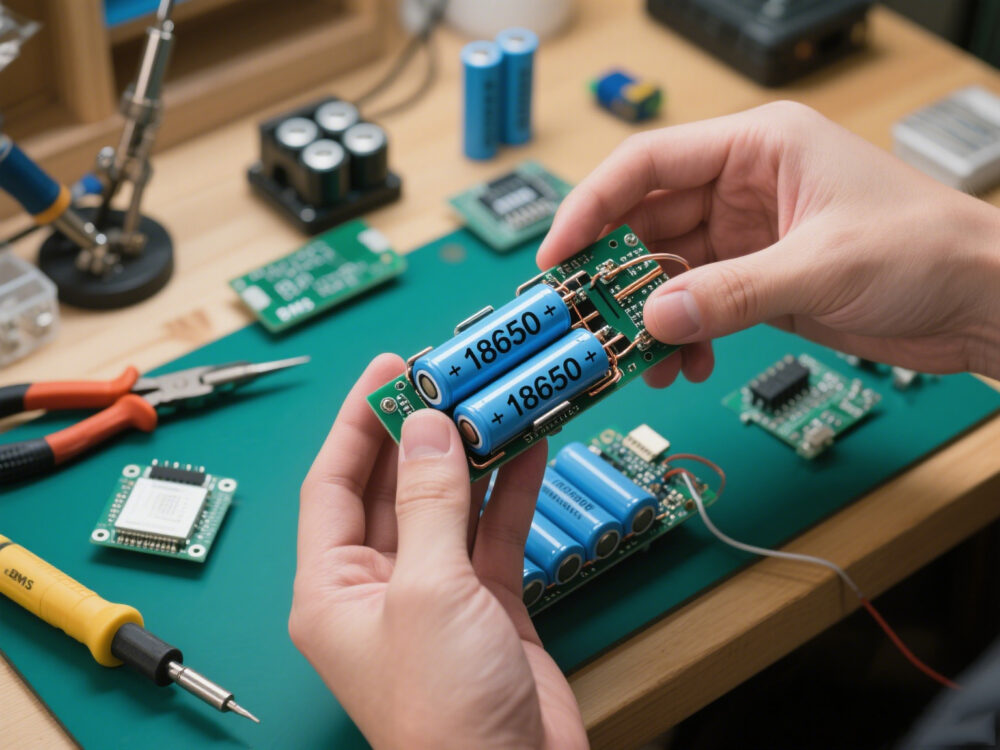

3. Can I Build My Own Custom Battery?

Yes, but it’s not as easy as it sounds. The process usually goes like this:

- Design the specs – Decide on voltage (36V, 48V, 52V, or even 72V) and capacity (20Ah, 30Ah, etc.) based on your motor power and expected range.

- Select cells – Common formats are 18650 or 21700 cylindrical cells. A pack might need dozens or even hundreds. Cell quality makes or breaks the battery.

- Assembly – Spot weld the cells into parallel and series groups (e.g., 13S4P for 48V). Poor welds can overheat or short.

- Install the BMS – This “brain” balances voltages and protects against overcharge, over-discharge, and short circuits.

- Enclosure and finishing – Add insulation, put everything into a case, and seal it against water and vibration.

It sounds straightforward, but mistakes are costly. Cells can overheat during welding, a mismatched BMS won’t function, and safety risks are real. DIY is possible for experienced builders, but most riders are safer leaving it to professionals.

4. What Key Specs Should I Know?

When talking to a builder or supplier, expect these terms to come up:

- Voltage (V) – Determines motor power. 36V is entry-level, 48V/52V is common, and 72V is for high-performance builds.

- Capacity (Ah) – Think of it as fuel tank size. 15Ah works for daily commuting; 30Ah+ is for long-distance trips.

- Cell type – Higher-grade cells last longer and run cooler.

- Shape – Packs can be rectangular, triangular, split, or even curved, depending on your frame.

- Connectors & BMS – Critical for safe charging and discharge.

5. Is a Custom Battery More Expensive?

Yes, usually. Reasons include:

- One-off design and hand assembly instead of mass production.

- Extra testing and sometimes custom cases.

But consider this: a cheap stock battery might die in 2 years, while a custom pack can last 5. Over time, it can actually be more cost-effective.

6. What Should I Watch Out for When Using a Custom Ebike Battery?

- Use the right charger – Never swap chargers from other packs.

- Store at partial charge – If unused, keep the battery at 40–60% rather than empty.

- Avoid extreme temps – Don’t charge under the sun or in sub-zero weather.

- Check regularly – Look for loose connectors, swelling cases, or strange smells. If anything seems off, stop using it immediately.

7. Who Really Needs a Custom Ebike Battery?

- Long-distance riders – Touring cyclists who need 100+ km per charge.

- Delivery riders – Couriers who can’t afford downtime.

- Performance enthusiasts – Builders who push motors and controllers beyond factory limits.

- Unique frame owners – Folding or niche frames that can’t fit a standard pack.

8. Where Can You Get One?

Three main routes:

- Professional builders or factories – Best for reliability and safety.

- Bike shops with modification services – Some offer install and fitment.

- DIY communities – Forums and maker groups, if you want to learn and experiment.

Final Thoughts

A custom ebike battery isn’t a luxury — it’s a solution.

It frees you from the limits of “standard packs” and lets your bike fit your life. If you just ride short commutes, stock batteries are fine. But if you need more range, power, or special fitment, a custom battery is the way forward.

The only decision is: do you trust your own technical skills enough to DIY, or do you want to hand the job to someone experienced?

-

Curved Battery FAQ: A Guide for Wearable Device Battery Sourcing

As wearable electronics get smaller and more ergonomic, traditional square or cylindrical batteries often just don’t fit. That’s where curved batteries come in. Their arc-shaped design allows engineers to make the most of limited space, hiding the battery inside rings, bracelets, or wrist-worn smart devices. Here’s a FAQ guide for anyone looking to source these batteries.

1. What is a Curved Battery?

In simple terms, it’s a lithium polymer (LiPo) battery designed with a specific curvature from the start. Unlike flexible batteries that bend like a rubber band, curved batteries are manufactured in a fixed arc shape. This allows them to fit snugly inside rings, wristbands, or curved device enclosures without wasting space.

2. What devices are they used in?

Curved batteries are primarily aimed at the wearable market:

- Smart rings

- Fitness trackers and smartwatches

- Miniature wearable sensors

- Medical-grade wearable devices

If your product is small enough to fit on a finger, standard batteries are either too thick or simply won’t fit. Curved batteries solve that problem perfectly.

3. What are typical specifications?

Wholesale buyers usually care about voltage, capacity, and dimensions. Typical specs include:

- Voltage: usually 3.7V, which is standard for LiPo cells.

- Capacity: ranges from 8mAh to 30mAh, with smart rings often needing around 10–20mAh.

- Dimensions: width, thickness, and curvature can be extremely small, e.g., 1.5mm thick models that fit inside smart rings.

- Cycle life: usually 300–500 charge/discharge cycles.

- Operating temperature: discharge -20°C to 60°C, charge 0°C to 45°C.

Though the numbers seem modest, they’re enough to power heart rate monitoring, Bluetooth, and other core features in miniature wearable devices.

4. Can they be customized?

Absolutely, and in most cases, customization is necessary.

Different rings and wristbands have different curves, so battery manufacturers typically design the battery to match your enclosure. Customization options include:- Curvature (e.g., π/6, π/3, half-ring shapes)

- Dimensions (thickness, length, width)

- Capacity (based on device power requirements and desired battery life)

- Connector or soldering options

If you finalize your case design before talking to the battery supplier, you might end up with a battery that doesn’t fit—a costly mistake.

5. Which manufacturers offer these batteries?

Currently, several manufacturers specialize in curved LiPo batteries:

- Professional LiPo manufacturers capable of making ring and arc-shaped batteries.

- Wearable device suppliers who often co-develop batteries with smart ring and wristband manufacturers.

For example, ANPS and GMB offer specific models with very thin profiles (1.5mm) and capacities ranging from 8–25mAh, designed for smart rings.

6. What should wholesale buyers watch out for?

If you’re sourcing in bulk, keep these points in mind:

- MOQ (Minimum Order Quantity): Custom curved batteries often require orders of several thousand pieces.

- Consistency: Small-capacity batteries must maintain consistent voltage and capacity across batches.

- Certifications: CE, UL, UN38.3—especially important for export.

- Lead time: Custom batteries usually take 4–6 weeks to produce.

7. Who should consider these batteries?

- Wearable device manufacturers: Startups making smart rings or fitness bands.

- Medical device developers: Miniature devices that need small, lightweight batteries.

- Electronics design companies: OEM/ODM projects requiring specialized battery shapes.

If your device draws high current (like drones or power tools), curved batteries are not suitable. But for lightweight, small, body-conforming wearables, they’re almost indispensable.

Summary

Curved batteries may be small in capacity, but in the wearable sector, they’re invaluable. They’re not “general-purpose batteries” but highly customized solutions. Wholesale buyers should consider not only voltage and capacity but also enclosure curvature, manufacturer customization ability, and batch reliability.

Bottom line: If you’re making smart rings, wristbands, or body-conforming wearables, curved LiPo batteries are a must-have component.

-

12V Drone Battery FAQ for Wholesale Customers

In the drone world, batteries aren’t just a component—they’re basically the heart of the whole operation. For wholesale buyers, knowing the ins and outs of a 12V drone battery, how it works, and how to handle it properly can save a lot of headaches down the line. Here’s a friendly, easy-to-understand FAQ to help you make smart choices.

What Exactly is a 12V Drone Battery?

A 12V drone battery is mainly used for lightweight or mid-sized drones. The appeal? It’s compact, packs a punch, and doesn’t weigh your drone down. Perfect for things like agricultural drones, aerial photography, and even industrial inspections.

Basically, these batteries give you enough juice to keep the drone flying efficiently while keeping the craft light enough for smooth handling. Think of it like choosing a lightweight backpack for a long hike—you want enough storage without being weighed down.

Why You Can’t Ignore the BMS

The Battery Management System (BMS) is basically the battery’s brain. Without it, your battery is flying blind. Here’s why it matters:

- Voltage & Current Monitoring: Stops overcharging or draining too much, protecting the battery.

- Temperature Management: Keeps it from getting too hot or too cold—both are bad for performance.

- Performance Tweaks: Adjusts output depending on how hard your drone is working.

In short, a battery without a BMS is like driving a car without a dashboard—you have no clue what’s going on. For wholesalers, offering batteries with a solid BMS is a smart move because it cuts down on returns and complaints.

How Long Will a 12V Drone Battery Last in the Field?

Flight time varies. Here’s what affects it:

- Battery Size: Bigger batteries = longer flight.

- Payload & Spraying Load: Heavier loads drain the battery faster.

- Environment: Wind, temperature, and even terrain can mess with efficiency.

Some ballpark figures:

- Mid-sized agricultural drones (10–15L spray capacity) usually get 12–16 minutes per charge.

- Heavy-duty batteries can stretch that to 40–60 minutes when carrying lighter loads.

So, when picking batteries for your clients, it’s smart to match capacity to what they’ll actually use.

Charging Tips to Keep Your 12V Batteries Happy

Charging might seem basic, but it’s super important for battery life:

- Stick to the Manufacturer’s Charger—no substitutes.

- Check for Damage—don’t charge a swollen or leaking battery.

- Charge Safely—pick a ventilated area, away from flammable stuff.

- Avoid Overcharging—unplug once it’s full.

- Keep an Eye on It—don’t just walk away; watch for anything unusual.

Following these simple steps will make your batteries last longer and keep things safe.

Buying Tips for Wholesale Customers

- Go for Batteries with a BMS—it’s worth it.

- Pick Capacity Based on Use—different drones need different power.

- Look at Cycle Life—good batteries handle around 1,000 charge cycles.

- Consider Protection—waterproof and corrosion-resistant batteries are better for outdoor use.

Wrapping It Up

A 12V drone battery is the unsung hero of any drone operation. For wholesalers, knowing the tech, picking the right models, and giving your clients clear guidance goes a long way in building trust and cutting down returns.

Pro Tip: Include a simple “Battery FAQ” sheet with your products. It helps users understand BMS, charging tips, and flight times. Trust me, it makes life easier for both you and your clients.

-

How to Replace 18650 Batteries in Solar Lights: Practical Guide with Tips and Real-World Cases

Introduction: Why Solar Light Batteries Matter

In the hot summers of Ontario, California, almost every backyard is lit with solar garden lights. At first, they shine brightly and last through the night. But after several months to a year, brightness fades, and nighttime runtime shortens—a very common issue.

Battery degradation is usually the culprit, though many assume the solar panel is failing. In reality, if your light can’t stay on all night after several sunny days of charging, the battery is likely worn out.

Replacing the 18650 battery is the simplest fix. Done correctly, it can restore brightness and extend your light’s lifespan by another 1–2 years.

Overview of 18650 Batteries

18650 batteries are cylindrical lithium-ion cells with a standard size: 18mm diameter × 65mm length. Capacity typically ranges from 1500mAh to 5200mAh.

Common Types

ICR (Lithium Cobalt Oxide): High energy density, best for compact lights requiring long runtime. Moderate discharge rate, not ideal for high-power LEDs. Thermal stability is average, so caution is needed in hot climates.

Case Study: Small garden lights in Brooklyn, NY using ICR cells performed reliably but drained a bit faster during summer heat.

INR (Lithium Nickel Manganese Cobalt Oxide): Strong discharge capability, suitable for high-brightness LED lights. Thermal stability is average, requiring proper protection against overheating. Best for flagpole or flood-style garden lights.

LiFePO4 (Lithium Iron Phosphate): Excellent thermal stability and long cycle life, though slightly lower capacity. Performs well in hot outdoor environments and continuous-use setups like courtyard lights.

Important Notes

Most solar lights are designed for either 3.2V or 3.7V batteries. Using higher voltage can damage circuits.

ICR and INR cells usually output 3.6–3.7V, generally safe for direct replacement.

LiFePO4 batteries are 3.2V—compatibility must be checked before use.

Always choose PCM-protected batteries to avoid overcharge, over-discharge, and short-circuit risks.

Choosing the Right Replacement Battery

Capacity

In Brooklyn, NY, one community tested old 1500mAh batteries that powered lights for about 4 hours. After upgrading to 2500mAh batteries, runtime extended to 6 hours, with brightness up about 30%.

Tip: Bigger is not always better. If the light’s circuitry only supports 1500–2500mAh, oversized cells may not fully charge—or worse, may overheat.

Battery Type

ICR: Best for small lights, long runtime, mild climates.

INR: Best for high-brightness LEDs requiring strong discharge, e.g. flagpole or spotlight use.

LiFePO4: Best for long-term outdoor use, high heat tolerance, and slow nightly discharge.

DIY Tip: Different brands have different discharge curves—mixing brands or chemistries can cause unstable performance.

Step-by-Step Installation (Hands-On Guide)

Tools Needed: Small Phillips screwdriver, insulated gloves, new 18650 battery.

Disassemble the light – Rotate the base counterclockwise or remove screws. Take care not to damage the waterproof seal.

Remove old battery – Note polarity before taking it out.

Insert new battery – Align positive and negative ends correctly.

Reassemble the housing – Ensure the waterproof ring is sealed to prevent rain damage.

Test brightness – Charge fully in sunlight, then check nighttime brightness and runtime.

Practical Note: Be careful with wiring near the solar panel. Older lights may have brittle plastic clips that snap easily during disassembly.

FAQ

How much brighter will the light be after replacement?

Field tests in Brooklyn showed a 30% brightness boost and 1.5–2 hours longer runtime when upgrading from 1500mAh to 2500mAh batteries.

How do I know it’s time to replace the battery?

Noticeable brightness drop.

Runtime under 80% of original spec.

Even after sunny days, the light fails to last overnight.

Are all 18650 batteries suitable for solar lights?

No. You must check:Voltage (3.2V vs. 3.7V).

Chemistry type.

Protected vs. unprotected cell.

Manufacturer consistency—mixing can cause instability.

Conclusion

Replacing the 18650 battery is the most straightforward way to revive solar lights. By selecting the right capacity, chemistry, and brand—and following careful installation—you can extend your light’s lifespan and restore strong nighttime illumination.

-

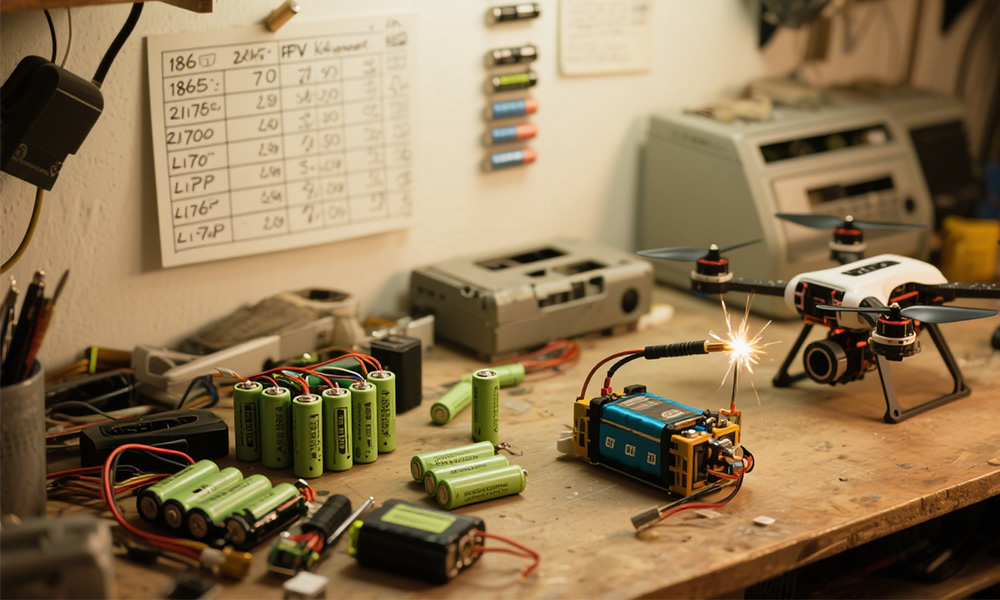

DIY Drone Battery Pack Design Guide: From Chemistry to Real-World Flying

“Who says ‘do it yourself’ means peace of mind? Ever had that moment when you built your own pack, took it for a flight, and nearly started questioning your whole existence?” — I still remember my first pack failure at the field: the cells hissed like a ticking bomb, and before my brain caught up, I was already clutching my 7-inch long-range quad and sprinting for safety.

1. Why Even Build Your Own Battery Pack?

Aren’t there enough batteries on the market? Why take the risk and make your own?

If you’ve ever hung out on r/fpv, you’d know — DIY battery packs aren’t just about saving money. They’re FPV’s version of “adult LEGO,” letting you bake your flying style into every single cell.But seasoned pilots have been saying it for years:

“Pick only one: long flight time or high power. Real-world physics doesn’t let you have both.”

I first saw this line on a Reddit thread and thought, yeah, right. Six months later, lugging an 8.4Ah 6S2P pack that had me shaking mid-flight, I had to admit — this was physics talking, not conspiracy theory.

2. Electrochemistry Basics: Don’t Fall for the Marketing Hype

We’ve all heard “high C-rating,” “high energy density,” “RC-special” thrown around — but the real differences only show in the air.

LiPo (Lithium Polymer)

Pros: Light, high discharge rate, instant punch

Cons: Fragile, puffs if pushed too hard, the most common “dead soldier” at the field

My take: Once flew a 6S 1500mAh LiPo on a 35°C summer day — 5 minutes later it puffed up like a steamed bun.

Li-ion (18650 / 21700)

Pros: High energy density, good durability, long cycle life

Cons: Lower discharge rate, not great for aggressive freestyle

3. Spec Sheet Traps: Lab Numbers Don’t Live in the Field

Open a cell manufacturer’s datasheet and everything looks great — but those numbers only live in lab conditions.

Big capacity ≠ long flight: That giant pack you think will give you insane flight time might end up killing it with weight before you get halfway.

High C-rating ≠ endless punch: Sure, it’ll rip hard, but voltage sag will hit you like an elevator drop.

Series/Parallel setups:

4S2P → Stable, beginner-friendly

6S2P → Balance of range and punch

6S3P → Range monster, but without a reinforced frame you’re asking for snapped arms.

I once grabbed some “perfect spec” 21700 P50Bs at an electronics market. Looked flawless on paper. In the air? Massive sag. Found out later they were refurbs. That’s what skipping internal resistance testing gets you.

4. Safety: Don’t Turn the Flying Field into a Fireworks Show

LiPo explosion clips are all over YouTube, but the real thing is quieter — at first. It starts with a puff, then a nasty chemical smell, then a flash of runaway flames.

I’ve seen a guy’s LiPo start smoking 10 seconds after landing — the extinguisher didn’t even make it over before he was already sprinting away.

Thermal runaway threshold: 3.2V per cell is a red line. Don’t be the hero who drains to 2.8V — you’re basically making a slow-cooking time bomb for the next charge.

My safety kit:

3kg ABC fire extinguisher

Fireproof charging bag (never charge bare)

Voltage alarm (live in-flight alerts)

5. Field Tests: Data Only Counts When You’ve Burned Packs for It

I don’t trust manufacturer claims — I run my own tests.

35°C uphill wind: 6S 7Ah Li-ion, theoretical 20 min — cut off at 8 min due to heat throttling.

Back mountain ridge: 6S2P 8.4Ah P42A, 19 min flight, cells at 68°C, just shy of triggering cutoff.

Winter night flight: LiPo 1500mAh at 4°C, lasted 2 min before sagging to 3.4V. Cold is the silent killer.

6. The Eternal Trade-Off: Fly Longer vs. Fly Harder

You want range? Stack cells, and your frame turns into a bricklayer’s loadout.

You want to rip trees? Go light, and 4 minutes of flight time is all you’ll get.Some folks chase the mythical “one pack for everything” — but in the real world, that’s a joke. The pros pack different batteries for different jobs, like a photographer swapping lenses for weddings vs. wildlife.

7. My Build Process (New Pilots Can Copy-Paste)

Pick cells: Buy from reliable sources (yes, the good electronics market stalls count).

Welding: 0.15mm nickel strip, spot welder set around 400A — strong joints without cooking the cell.

Protection: Add a 5A BMS, shrink wrap, foam padding on the edges.

Testing: Let the pack sit for 12h, watch for leakage or abnormal self-discharge.

Flight trials: Hover test under light load, then full-send at the field — check temps and sag behavior.

8. Final Words: The Romance of Flight Isn’t in the Datasheet

“Flight isn’t the thrill of numbers on paper — it’s when you haul your cells up a mountain, into the wind, into the wild, and see if they’re truly alive.”

Every cell you weld is just a cold number — until you stand on a mountaintop, watch it take your quad 2km out and back, steady and sure. That’s when it has a heartbeat.

-

Li-ion Batteries for Drones: A Flight Time Revolution or Just More Trouble?

When it comes to drone batteries, most people immediately think of LiPo (Lithium Polymer). But I want to say—don’t be blinded by the “high discharge rate” hype. After tinkering with DIY Li-ion battery packs, I was surprised to find that 18650 cells are actually the secret weapon for long-endurance FPV. Of course, this path isn’t exactly smooth sailing.

Li-ion VS LiPo: The “Old Battle” of Energy Density vs Discharge Rate

Simply put, Li-ion’s energy density is irresistibly high, extending flight time by over 30%. No exaggeration, it’s real. A 4S 6000mAh Li-ion pack easily achieves 25 minutes of flight, keeping throttle around 60%, and still retains 20% battery at landing. Compared to LiPo’s short and intense “sprint” of 15 minutes, it’s a world of difference.

That said, Li-ion’s lower discharge rate is a fact. The high C-rating “discharge efficiency” parameters you see elsewhere simply don’t apply here. If you want to do aggressive racing or freestyle, better stick with LiPo—they deliver the power you need. This comparison is contradictory: for long endurance and top performance, is it really a choice between one or the other?

The Pitfalls and Joys of DIY Battery Packs

DIY battery packs? Don’t believe all the online talk about how easy it is. I soldered those 18650 cells together, but at first the Battery Management System (BMS) wasn’t installed correctly, causing unbalanced charging issues. One time, my battery pack cut off power unexpectedly on the way home—that was terrifying. Later, after switching to a protection board with balance leads, the battery finally stabilized.

On the design side, I made sure to leave space for “soft connecting wires” to prevent solder joints from breaking due to vibration—something I realized only after weeks of tweaking. Beginners, please don’t skip this step like I did, or your battery might “say goodbye” mid-flight.

Real Experience with Long-Endurance Flights

A few months ago, I took my self-made 6S 6000mAh Li-ion battery to an amateur FPV flying meet. Although the larger battery made the drone noticeably heavier at takeoff, stability actually improved quite a bit. That day, I flew nearly 20+ minutes while others were still swapping batteries. I felt like I was holding a “gold brick” compared to their “rocket fuel.”

However, long endurance doesn’t mean just pure “fun.” It demands new tactics—strict monitoring of battery temperature during flight. Li-ion batteries degrade and risk safety if they overheat. I witnessed a scary incident where a battery swelled and almost blew up because the temperature wasn’t watched closely.

What’s Next in the Battery “Arena”?

So, is Li-ion the future for long-endurance drones? Maybe, but it’s definitely not a cure-all miracle. Solid-state and lithium metal batteries show promising research progress, but in the short term, the contradiction between DIY pack making and stable flight will persist.

My own view is: always prioritize safety over flight time. Blindly chasing large capacity while neglecting BMS and thermal management is a dead-end road.

Summary and Recommendations

- If you want long flight times, choose Li-ion cells, don’t blindly chase high C-ratings;

- When DIY-ing battery packs, pick a good BMS, install balance leads and protective circuits properly, don’t skimp on these;

- Always bring a thermal gun to the flying field to monitor battery temperature in real time, preventing dangerous battery failures;

- Long-endurance flying demands both technical know-how and strong safety awareness—it’s not just about buying a big-capacity battery.