Your cart is currently empty!

Category: Battery FAQ

-

How to Choose the Right Drone Battery? A Must-Read Guide for Buyers

Why Is Drone Battery Procurement Critically Important?

Commercial drones are widely used in agriculture mapping, security patrols, and logistics. Their operational efficiency and flight stability heavily rely on battery performance. The battery type, capacity, and discharge efficiency directly impact flight time, mission success, and safety control.

In today’s fast-growing drone market, batteries are no longer just power sources—they determine mission duration, operational reliability, and cost-effectiveness.

For procurement professionals, battery selection isn’t just about price. It must address:

- Suitability for the application scenario (e.g., crop spraying vs. urban inspection)

- Durability and reliability to minimize after-sales service

- Customization to fit various drone platform designs

Choosing the right battery helps avoid flight interruptions, reduces replacement frequency, and cuts operational costs.

Comparison of Mainstream Drone Battery Types

1) Lithium Polymer Battery (LiPo Battery)

- Pros: Lightweight, high discharge rates, ideal for high-speed drones

- Cons: Requires careful charging/discharging; needs dedicated charger and BMS

- Features: Very high discharge rate (up to 30C+), low weight

- Best for: Racing drones, crop-spraying drones, high-power applications

- Caution: Prone to swelling; must avoid overcharging/discharging

2) Lithium-ion Battery (Li-ion Battery)

- Pros: Long cycle life, high energy density, suitable for long-duration missions

- Cons: Lower discharge rate, not ideal for burst current applications

- Features: Excellent energy-to-weight ratio, long lifespan, good thermal stability

- Best for: Fixed-wing drones, long-endurance surveillance drones, delivery drones

- Caution: Lower discharge rate (≤3C), not suitable for sudden high-current demands

How to Match Battery Capacity with Flight Time?

Battery capacity and flight time are key metrics for drone buyers. Use the formula below:

Flight time (min) ≈ Battery capacity (mAh) × Voltage (V) ÷ Power consumption (W) × 60

Example: A 6S battery (22.2V) × 10,000mAh (10Ah) used in a drone with 500W power draw:

10Ah × 22.2V ÷ 500W × 60 ≈ 26.6 minutesProcurement Tips:

- Match battery capacity to the drone’s max payload and expected flight redundancy (keep 20%–30% capacity margin)

- Higher voltage reduces current and cable losses—ideal for high-power systems

- For endurance-focused drones, consider series/parallel battery configurations

Safety Maintenance: A Key Procurement Priority

Drone Battery Safety Checklist:

Equipped with BMS (Battery Management System)

Supports balanced charging

Includes overvoltage, overcurrent, and short-circuit protection

Certified with UN38.3 / MSDS / CETransport Regulations: Critical for Cross-border Procurement

Drone batteries for air transport must pass the UN38.3 test

Packaging must be shockproof, insulated, and anti-static

Proper labels like “Contains Lithium Battery” are mandatory for shipping

Summary of Procurement Recommendations

Dimension Recommendation Battery Type Use Li-ion for long missions; LiPo for high burst power Capacity Selection Estimate flight time, then add 20% safety margin Safety Certifications Prioritize batteries with MSDS, UN38.3, and CE Supplier Standards Choose vendors offering customization, after-sales support, and shipping compliance Conclusion

Procuring safe and high-performance batteries is the first step toward successful drone operations. Whether your drone serves agricultural spraying, energy inspection, or delivery missions, a high-quality battery underpins operational efficiency, safety, and cost control.

To ensure procurement success, always choose the right battery type, a compliant brand, and an experienced manufacturer. -

How to Choose 18650 Batteries for Different Industries: A Wholesale Application Guide

Why 18650 Batteries Are Widely Used

18650 lithium batteries have become the go-to power solution for a wide range of small and medium-sized devices due to their high energy density, rechargeable design, standardized size (18mm×65mm), and excellent cost-performance ratio.

Key advantages include:

- Stable voltage output (typically 3.6V or 3.7V)

- Long cycle life (500–1000 cycles)

- Easy to assemble into series-parallel battery packs

- Suitable for consumer electronics, power systems, medical, and industrial products

Wholesale Applications in LED Lighting & Flashlights

LED lighting devices such as high-power flashlights, mining lamps, and camping lights commonly use 18650 batteries.

Procurement Suggestions:

- Recommended Capacity: 2200mAh–3000mAh

- Cell Type: High discharge rate with built-in protection circuit

- Key Considerations: Compact space requirements, prefer lightweight and low internal resistance models

High-Rate 18650 Cells for Power Tools

Power tools like electric drills, impact wrenches, and lawn trimmers require high pulse current discharge, demanding much from battery performance.

Recommended Configurations: 3S2P / 4S1P / 5S2P packs

Cell Type: Discharge rate ≥10C–20C, supports high current bursts

Protection: Integrate with BMS to prevent overcurrent and overheating

Consumer Electronics (Speakers, Fans) Bulk Integration Plans

Bluetooth speakers, handheld fans, and cordless vacuums require mid-level battery performance.

Recommended Specs: 2000–2600mAh standard cells

Cell Type: Grade A 18650 cells

Features: Supports PCBA customization to match device design

Safety and Certification Needs in Medical Devices

Medical equipment such as portable oxygen concentrators and health monitors demand highly reliable battery solutions.

Cell Recommendation: Prioritize stability, choose Grade A cells

Certifications Required: UN38.3, MSDS, CE, etc.

Customization Services: Offers shell encapsulation, flame-retardant ABS materials, SMT connector designs

18650 Pack Solutions in Energy Storage and Solar Applications

Home energy systems, solar street lights, and telecom base stations need high-capacity, long-life batteries with scalability.

Recommended Configurations: 13S4P / 14S3P / 16S5P large series-parallel packs

Cell Suggestion: Use LiFePO4 18650 cells for longer cycle life

Special Note: Pair with BMS and metal battery enclosures for system stability

Conclusion

Though 18650 batteries follow a standard form factor, their performance requirements vary greatly across applications. When purchasing in bulk, consider capacity, discharge rate, certifications, and structural design, and consult with professional suppliers for customized solutions. This ensures cost-effective procurement and stable product performance.

-

Electric Scooter Battery Cell Procurement Guide: How to Find Quality 18650 Supplier?

Why Do Electric Scooters Prefer 18650 Battery Cells?

The 18650 lithium cell has become the mainstream power solution for electric scooters due to its high energy density, excellent cycle life, and reliable current output capability. Its mature structure and stable supply chain also help reduce overall vehicle costs and ease after-sales maintenance.

How to Evaluate the Quality of 18650 Battery Cells?

Assess the quality based on the following key factors:

- Capacity Consistency: Poor consistency affects range and safety.

- Internal Resistance: Lower is better; ideally below 60mΩ.

- Cycle Life: Premium cells typically offer over 500 cycles.

- Discharge Capability: Match 5A–15A discharge for scooter motors.

Key Battery Cell Specifications for Matching Scooter Power Systems

Electric scooters have strict requirements for their battery systems:

- Nominal Voltage: 3.7V per cell

- Common Configurations: 10S2P (36V), 12S2P (43.2V), etc.

- Capacity Range: Typically 4Ah to 10Ah

- Discharge Rate: Choose high-rate cells that align with the scooter’s controller

- Operating Temperature: Ensure stable performance in high-temperature regions

Five Criteria for Selecting a Reliable 18650 Battery Cell Supplier

- Certifications: Look for UN38.3, MSDS, CE, RoHS, etc.

- Customization Support: Voltage, current, and size customization

- Sample Consistency Testing: Can the supplier offer batch samples and test reports?

- Lead Time and Capacity: Can they meet regular supply and bulk orders?

- Service Capability: Do they offer after-sales, technical support, and BMS matching advice?

Common Issues in Battery Procurement and How to Avoid Them

- Avoid focusing only on unit price while neglecting consistency and lifespan

- Test a small batch before placing large-scale orders

- Communicate with the battery pack assembler to confirm compatibility with the BMS and housing design

Conclusion

For electric scooter manufacturers and battery wholesalers, choosing a high-quality 18650 cell supplier impacts not only product performance and safety but also your brand reputation and customer satisfaction. We recommend partnering with professional manufacturers that offer certifications, stable supply, and after-sales support, aligning with your product positioning.

-

How to Choose the Right 18650 Rechargeable Battery for Your Product

Capacity Selection: How 2000mAh-3500mAh Affects Runtime

Capacity directly impacts device runtime. Common options:

2000mAh-2500mAh: Weight-sensitive devices (e.g., Bluetooth speakers, handheld instruments)

2600mAh-3000mAh: Balance cost & runtime (e.g., power tools, LED lighting)

3100mAh-3500mAh: High-endurance applications (e.g., E-Bikes, solar storage)

Tips:

Low-power devices → Prioritize cost with 2000-2500mAh

High-power devices → Choose 3000mAh+ to reduce charging frequencyDischarge Rate (C-rate): Match Your Device Power Needs

Discharge rate determines instantaneous power output:

1C-3C (Standard): Low-power devices (e.g., vapes, small appliances)

5C-10C (Mid/High-rate): Fast-drain devices (e.g., drones, power tools)

15C-30C (Ultra-high): Industrial equipment, jump starters

Note:

High-rate batteries cost more; select based on actual needs

Continuous high-current discharge may shorten lifespanBMS Matching: Core of Safety & Smart Management

BMS (Battery Management System) ensures safety & longevity:

Basic Protection: Overcharge/over-discharge/short-circuit (mandatory)

Advanced Features: Cell balancing, temperature monitoring (premium devices)

Customization: Communication protocols (e.g., UART, I2C) for smart devices

ODM Advice:

Budget products → Basic BMS to control costs

High-end/industrial devices → Custom BMS with data monitoring

Conclusion: 3 Steps to the Perfect 18650 Battery

Set Capacity → Choose 2000-3500mAh based on runtime

Set Discharge Rate → Match 1C-30C to power requirements

Set BMS → Select protection level per safety needs

-

How to Choose the Best Electric Bike Battery Size,Professional Selection Guide

Basic Concepts of Electric Bike Battery Size

Battery size typically refers to the physical dimensions and capacity (measured in ampere-hours, Ah). A larger capacity means a longer theoretical range, but also leads to increased size and weight, affecting the bike’s handling and comfort.

Key Factors Affecting Battery Size Selection

When choosing a battery size, it’s essential to consider:

- Space limitations of the bike’s design

- Required range (short-distance vs. long-distance travel)

- Load and power demands of the bike

- User preferences between range and portability

Common Electric Bike Battery Sizes and Capacity Options

Image Title: Comparison Chart of Common Battery Capacities

Image Alt: Size and capacity comparison of 36V and 48V batteries

Image Description: Range and size illustrations of batteries with different voltages and capacities- Small-capacity batteries (under 10Ah): Best for lightweight, short-range models with 20–40 km range

- Medium-capacity batteries (10–15Ah): Ideal for daily commuting with 40–70 km range

- High-capacity batteries (15Ah+): Suitable for long-distance or heavy-load use with over 70 km range

Additionally, common voltage ratings such as 36V and 48V influence both battery size and range performance.

How to Choose the Right Battery Size Based on Application

- City commuter bikes: Recommended 36V 10–15Ah batteries for moderate range and balanced weight

- Folding e-bikes: Prioritize lightweight, small-capacity batteries for easy transport

- Mountain e-bikes: Require high-capacity, high-voltage batteries for climbing power and extended range

- Cargo e-bikes: Need larger-capacity batteries to support longer operation and heavy loads

How Battery Size Affects Bike Performance

While large-capacity batteries improve range, they also increase total weight, which can impact handling agility and acceleration. Choosing the right size ensures a balance between portability and range—critical for both design and procurement.

Conclusion

Selecting the proper battery size should be based on user needs, bike structure, and performance goals. A well-planned battery strategy, aligned with market positioning and product design, ensures supply stability and customer satisfaction.

Choosing the right electric bike battery size is key to improving product competitiveness and user experience. Apsenx offers customizable lithium battery solutions with a wide range of sizes and capacities to help businesses create differentiated, high-performance products.

-

How to Store Electric Bike Battery Properly, Key Guide to Extending Lifespan

Why Battery Storage Matters

If you leave an electric bike unused for a long time and store its battery improperly, you risk capacity loss, chemical degradation, or even swelling and short circuits. By storing it correctly, you extend its service life and prevent safety hazards.

Pre-Storage Checks and Preparation

Before storing your battery, take the following steps:

- Check for any damage or swelling on the battery casing.

- Ensure the battery holds 50%–70% charge.

- Clean the battery terminals to prevent dust and corrosion.

- If the battery is removable, store it separately in a fireproof bag.

Ideal Environmental Conditions for Storage

Store your battery under the following conditions:

- Temperature: 10°C–25°C (avoid extreme heat or cold)

- Humidity: Low humidity, good ventilation

- Keep it away from direct sunlight or heat sources (e.g., radiators, stoves)

- Use a fireproof safety box or metal cabinet for added protection

Maintenance Tips During Long-Term Storage

If you plan not to use the battery for more than 3 months:

- Check the battery charge once every month

- Recharge to 60% if it drops below 30%

- Avoid keeping the battery at full or empty charge for extended periods

- For storage beyond 6 months, use a maintenance charger with trickle charging

Prohibited Actions and Safety Warnings

Never do the following when storing your battery:

- Leave it in humid or corrosive environments

- Let it touch metal objects (risk of short circuit)

- Store it at 0% or 100% charge for long durations

- Wrap it in plastic bags, which block proper heat dissipation

Good Storage = Long Battery Life

Electric bike batteries are costly. A proper storage strategy significantly improves their lifespan and performance stability. Whether you’re storing for the winter, during long-distance transport, or keeping backup inventory, mastering these storage techniques is essential.

Conclusion

Battery manufacturers should provide customers with storage manuals and adopt smart BMS (Battery Management Systems) that automatically monitor charge and temperature during storage. This ensures even greater safety.

If you need custom-designed electric bike batteries optimized for long-term storage, contact the Apsenx Lithium Battery Solutions Team. We offer high-safety, high-stability battery options for extended storage needs.

-

What Is the Best Battery Pack for Reclining Furniture? A Professional Selection Guide

Basic Requirements for Reclining Furniture Batteries

As smart home adoption grows, powered recliners are becoming common in homes, theaters, and healthcare settings. Compared to plug-in models, battery-powered recliners offer more flexibility, no wiring, and enhanced safety. The ideal recliner battery pack should meet the following requirements:

- Matches the motor voltage (typically 25.2V or 29.4V)

- Provides enough capacity to support multiple uses per charge

- Includes a reliable BMS for overcharge and over-discharge protection

- Supports fast charging or easy replacement

Battery Type Comparison: Lithium vs. Lead-Acid

The market offers two main types of batteries for recliners:

- Lead-Acid Batteries: Low cost, average durability, bulky and heavy—less suitable for lightweight furniture.

- Lithium-Ion Batteries (e.g., 18650 or Li-Po): Compact, lightweight, highly efficient in charge/discharge, and long-lasting.

Overall, lithium batteries have become the mainstream choice for recliners due to their high energy density and user-friendly features.

How to Choose the Right Recliner Battery Pack

When selecting a battery, consider the motor power, voltage, and usage frequency. Key parameters include:

- Voltage: Commonly 24V, 25.2V, or 29.4V—must match the motor controller

- Capacity: 2000mAh to 4000mAh is recommended to support multiple uses per day

- Connector Type: Must match the original plug, typically a DC port

- BMS Protection: Ensures safety against overcharge, over-discharge, and short circuits

Recommended Configuration:

7S1P 18650 lithium battery, 2500–3000mAh capacity, built-in BMSPortable vs. Built-in Battery Packs: Pros and Cons

- Built-in Batteries: Integrated within the chair, maintaining a clean appearance but harder to replace

- Portable Battery Packs: Detachable, easier to replace or charge—ideal for high-usage environments

For frequently moved or used furniture such as showroom recliners or medical beds, a portable battery pack is the more convenient choice.

Custom Battery Solutions for Reclining Furniture

As professional lithium battery manufacturer, Apsenx offers tailored battery solutions for electric recliners, sofas, and medical beds. Our offerings include:

- Voltage Range: 12V to 29.4V

- Custom Capacities: 2000mAh to 10000mAh

- Multiple Casing Options: ABS case, soft pouch, aluminum shell

- OEM / ODM Support

All our battery products are certified (CE, UN38.3) and suitable for the EU and US markets. We support bulk orders and fast delivery.

Conclusion

Whether you’re choosing a battery for a home recliner, hospital bed, or theater seat, the battery affects both performance and safety. A premium lithium battery pack with a reliable BMS ensures stability, longevity, and smart functionality.

Apsenx stands ready to provide safe, efficient, and high-performance lithium battery solutions to help you upgrade your powered furniture. -

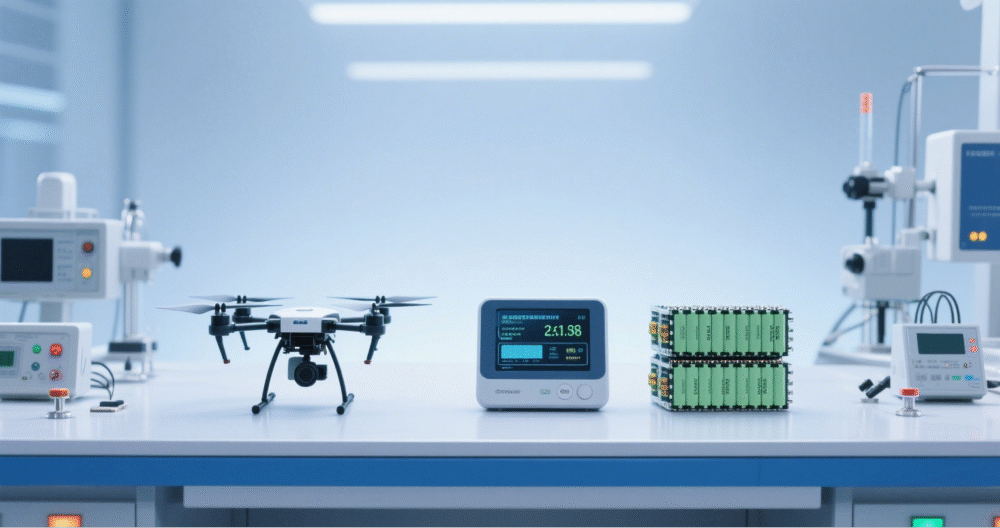

Custom Battery Packs for Long-Flight Drones: What to Consider

Why Long-Flight Drones Rely on Custom Battery Packs

Long endurance is a core performance factor for industrial drones, especially in tasks such as mapping, power line inspection, and agricultural spraying. Standard batteries often fail to meet the precise requirements of different drone models in terms of size, voltage, capacity, and discharge rate. Custom battery packs offer an effective solution to increase flight time and operational efficiency. With a well-engineered design, custom batteries can also enhance flight safety and system stability.

Cell Selection: The Core of Endurance and Safety

The battery cell serves as the core of a pack, and its performance determines the energy density and lifespan of the entire battery system. Common types include 18650, 21700, and high-power pouch cells. For long-flight drones, it’s essential to use cells with high energy density, stable discharge capabilities, and long cycle life. For example, 21700 cells outperform 18650 in terms of energy density and heat dissipation, making them a preferred choice for high-capacity battery packs.

Balancing Battery Capacity and Voltage Design

Battery capacity directly affects flight time, while voltage impacts motor efficiency and power consumption. A well-balanced configuration—such as 6S or 12S systems—must match the drone’s voltage platform and also take flight duration, current load, and equipment power consumption into account. When designing a custom battery, engineers must balance capacity, voltage, and weight to achieve the best energy-to-weight ratio.

Battery Structure Layout: Adaptability and Heat Dissipation Matter

Long-flight drones often have strict requirements for battery structure. A custom battery must precisely fit the drone battery bay, use lightweight materials to reduce payload, and include effective heat dissipation pathways to prevent overheating during long missions. A smart internal layout of cells and BMS modules improves both structural integrity and maintenance efficiency—especially for heavy-duty drones or prolonged flight scenarios.

Smart Battery Management System (BMS) Ensures Flight Safety

Long endurance requires longer battery operating cycles, making the Battery Management System (BMS) vital. BMS monitors temperature, voltage, and current in real time to prevent overcharging, over-discharging, and short circuits. Advanced BMS systems also support Bluetooth, CAN, or UART communication, enabling real-time data transmission between the battery and flight control system for enhanced operational safety.

Custom Battery Solutions for Long-Endurance Drones

Apsenx specializes in designing and manufacturing lithium battery packs for industrial drones. We offer a wide range of voltage platforms (such as 11.1V, 22.2V, 44.4V) and custom capacity solutions tailored to agricultural, mapping, and inspection applications. By optimizing cell configuration, modular structure, and integrated BMS, our solutions can extend drone flight time by 30% to 50%, while maintaining high safety standards in complex operating environments.

Conclusion

As the demand for extended drone flight time continues to grow, off-the-shelf battery solutions no longer meet the refined needs of diverse applications. Choosing the right battery cell, voltage configuration, structural layout, and BMS system is essential to building a high-performance custom battery pack for long-endurance drones. Apsenx remains committed to delivering professional, efficient, and safe battery customization services—empowering drones to perform at their full potential.

-

Why Long Battery Life Matters for Agricultural Drones

Definition and Importance of Long-Endurance Agricultural Drones

Agricultural drones are unmanned aerial vehicles used in farming tasks such as seeding, fertilizing, crop protection, and monitoring. As agricultural automation advances, Drone battery endurance becomes a key factor in evaluating a drone’s practicality. In large farmlands, frequent battery changes waste time and disrupt task continuity and data consistency. Therefore, drones with longer flight times better meet the dual demands of efficiency and precision in modern agriculture.

How Long Battery Life Improves Work Efficiency

Agricultural tasks like pesticide spraying and liquid fertilizer application require stable and prolonged drone flight. A long-endurance drone can cover larger areas in a single flight, reducing the need to return for recharging or battery swaps, which significantly boosts operational efficiency. Additionally, uninterrupted tasks lead to more even pesticide or fertilizer application, minimizing over- or under-application, and improving overall crop health.

Supporting Precision Agriculture: Data Integrity from Long Battery Life

Precision agriculture depends on image and sensor data captured by drones to analyze soil conditions, moisture levels, pests, and diseases. A long-endurance drone can complete full-field scanning and data collection in a single flight, ensuring data continuity and comprehensive coverage. This provides high-quality raw data for AI analysis and decision-making, helping elevate agricultural intelligence and management capabilities.

Battery Technology Enables Long-Endurance Drones

Recent advances in lithium-ion and LiFePO₄ battery technology have increased energy density, offering reliable power for long-endurance drones. Some premium agricultural drones also support customized battery solutions that optimize cell configurations and use upgraded Battery Management Systems (BMS) to enhance discharge efficiency and safety during extended flights. Meanwhile, lightweight structures and high-efficiency motors further contribute to longer air time.

Battery Solutions for Long-Endurance Agricultural Drones

As a professional lithium battery manufacturer, Apsenx provides customized battery solutions for agricultural drones, including 6S and 12S high-discharge-rate cell assemblies, intelligent BMS protection, and IP-rated enclosure designs. Our batteries are widely used in agricultural spraying and mapping drones, delivering 45–60+ minutes of flight time per mission, fully supporting frequent operation needs.

Conclusion:

In the wave of future agricultural automation, long-endurance drones will become essential tools for improving farming efficiency. Choosing drones equipped with high-performance batteries reduces maintenance costs and significantly improves task execution quality. Apsenx is committed to delivering reliable, safe, and durable lithium battery solutions for agricultural users, helping drive the future of smart agriculture forward.

-

How Long Do FPV Drone Batteries Last? Complete Breakdown of Key Factors Affecting Flight Time

1. How Long Do FPV Drone Batteries Usually Last?

FPV (First Person View) drones demand high power due to their fast speeds and acrobatic maneuvers. Most FPV drones fly for 3 to 10 minutes, depending on battery capacity, frame design, flying style, and weather conditions. Racing FPVs prioritize short bursts of power, while cinematic drones focus more on flight duration and stability.

2. Key Parameters That Affect FPV Battery Runtime

Several critical factors impact how long an FPV battery lasts:

- Battery Capacity (mAh): Higher capacity provides longer theoretical flight time.

- Voltage & Cell Count (S rating): Common configurations include 4S (14.8V) and 6S (22.2V). Higher voltage offers more power but drains faster.

- Discharge Rate (C-rating): Higher C-ratings deliver more current instantly, ideal for racing but shorten flight time.

- Payload: Heavier drones drain batteries quicker.

- Battery Health: Aged batteries with high internal resistance reduce efficiency and runtime.

3. Battery Performance Across Different Flying Styles

Racing Drones: Complete flights in under 5 minutes due to high speeds and powerful motors.

Freestyle Drones: Flight time ranges from 6–8 minutes depending on maneuver complexity.

Cinematic Drones: More power-efficient, often fly for 10+ minutes, typically use high-capacity, low C-rating batteries.

4. How to Extend the Lifespan of FPV Drone Batteries

To maximize battery lifespan and maintain consistent performance:

Charge Properly: Use balanced chargers and avoid overcharging.

Avoid Deep Discharges: Set low-voltage alarms during flight. Maintain a minimum of 3.5V per cell.

Store Smartly: When not in use, keep batteries at 3.7–3.85V per cell. Store in cool, dry places.

Check Battery Health: Regularly inspect for puffing or internal resistance spikes.

Use Quality Brands: High-quality batteries offer better consistency and safety.

5. Final Thoughts: Choose the Right Battery to Optimize Your Flight

Choosing the right battery for your flying needs—and maintaining it correctly—is key to maximizing flight time and safety. If you’re involved in manufacturing, assembling, or customizing FPV drones, we recommend exploring custom lithium battery solutions that meet specific flying demands and safety requirements.

Looking for high-performance FPV lithium battery solutions? We offer custom battery packs with flexible capacity, voltage, connector types, and battery management systems (BMS). Contact us today to discuss a tailored solution for your FPV drone applications.