Why Capacity Isn’t Just About the Numbers

When you’re buying batteries in bulk for electric devices, it’s surprisingly easy to make mistakes. Most people focus on capacity and price, pick the numbers that look best on paper, and hope for the best. Samples may seem fine, but when the full batch hits the devices, that’s when problems appear—short runtimes, heat issues, or packs failing earlier than expected. From my experience, the three things that really matter are capacity, heat management, and safety. Ignore any of them, and you’ll regret it down the line.

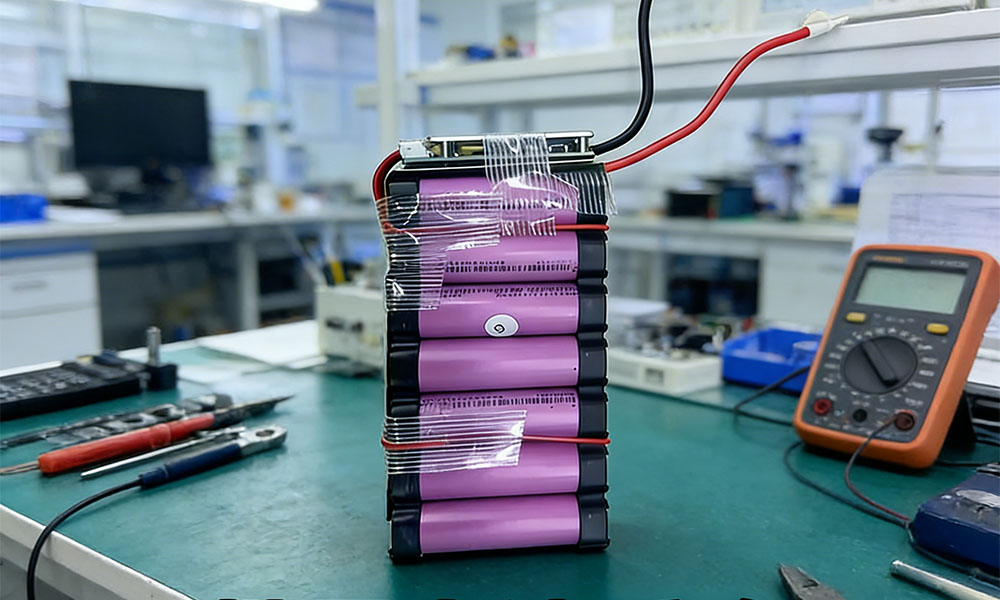

Capacity is the one everyone notices first, but it’s not about the biggest number. For wholesalers, what really counts is consistency across the batch and whether the cells match the device’s load. I’ve seen batches of “3000mAh” 7S2P battery packs where just a few weaker cells dragged down the whole pack. The BMS cuts power early, and the customer complains the battery doesn’t last. The practical way to handle this is to check the range of capacities and run a simple discharge test under load, rather than just trusting the datasheet.

The Importance of Heat Management

Heat is another common trap. Devices draw the most current when starting or running continuously, and if heat isn’t spread evenly—or if some cells have higher internal resistance—you get hotspots. That kills lifespan and can trigger protection circuits. In real projects, I always ask suppliers for internal resistance data and temperature behavior under sustained load. A pack that outputs steadily and heats evenly is far more reliable than one with a flashy peak rating that only lasts a few seconds.

Safety Can’t Be Optional

Safety is the last, and non-negotiable, piece. A proper BMS that covers overcharge, over-discharge, overcurrent, and short-circuit protection is essential. You also need a reliable supply chain—avoid second-hand or recycled cells. It’s tempting to save money, but the risk of rework, returns, or warranty issues is too high. Safety isn’t just about protecting a single cell; it’s about ensuring the whole pack behaves predictably in the device over its entire life.

How These Three Work Together

At the end of the day, these three factors work together. Capacity decides how long the device can run, heat management keeps it running reliably, and safety keeps the project low-risk. If you only focus on capacity or price, and ignore heat or safety, you’ll run into trouble sooner or later. Wholesalers aren’t just buying a good cell—they’re buying a battery system that works in the real device. Nail these three, and most of the headaches vanish.

Related Products

-

12V 4400 mah Lithium ion 3S2P 18650 Battery Pack

-

18650 20V 3.0Ah Cordless Drill battery

-

18650 22.2V 7.8Ah 2600Mah 6S3P Rechargeable Battery Pack

-

18650 3.7V 10Ah Li-Ion Power Battery Pack

-

18650 7S7P 24V 14Ah Lithium ion Electric Scooter Battery Pack

-

18650 Electric Scooter 48V 13000mAh Lithium Battery

-

2600mAh 3S1P 11.1V 18650 Battery Packs

-

36V 5200mAh 10S2P 18650 Battery Pack

-

48v 4400mah 13S2P 18650 Rechargeable Battery Pack

-

7S2P 24V 18650 Lithium Battery Pack

-

Electric Scooter 36V 4400mAH 10S2P 18650 Battery Pack

Leave a Reply