Your cart is currently empty!

Category: Battery FAQ

-

Where to Buy 18650 Batteries in Bulk for B2B Business

In the electronics and energy storage sectors, 18650 batteries serve as a cornerstone. Their versatility and wide range of applications make them highly sought-after components across many industries. If you want to purchase 18650 batteries in bulk for your business, this article will walk you through the key points—how to find reliable suppliers, understand battery specifications, and get the best deals.

1. Understanding 18650 Batteries

Capacity Range

18650 batteries typically offer capacities ranging from 1800mAh to 3500mAh. The capacity determines how much energy the battery can store. For applications that demand long-lasting power—such as high-end flashlights or portable medical devices—batteries with a capacity of 3400mAh to 3500mAh are often the preferred choice. For devices with lower power requirements, a capacity of 1800mAh to 2000mAh may be sufficient and more cost-effective.Cycle Life

Cycle life is another key factor. High-quality 18650 batteries can withstand hundreds or even thousands of charge-discharge cycles. For example, some top-tier lithium-ion 18650 batteries retain a significant portion of their original capacity even after more than 500 cycles. This makes them essential for products requiring long-term, repeated use—like power tools or off-grid energy storage systems.2. Where to Find Reliable 18650 Battery Manufacturers and Factories

Apsen Technology stands out as a dependable channel for bulk 18650 battery sourcing. With years of experience in the battery manufacturing industry, Apsen Technology offers a wide selection of 18650 batteries in various capacities and specifications to meet diverse B2B needs. Whether you’re looking for standard 18650 cells for consumer electronics or customized solutions for industrial applications, Apsen Technology can be your ideal partner.

You can directly contact Apsen Technology to discuss your bulk purchase needs, including order quantity, preferred capacity, and any custom requirements. They can provide detailed product information and competitive pricing.3. 18650 Battery Wholesale Pricing

Two main factors affect wholesale pricing for 18650 batteries: order quantity and battery capacity.

Quantity-Based Pricing

Generally, the more you order, the lower the unit price. Suppliers often use a tiered pricing structure. For example, small batch orders of 100 to 500 units tend to have a higher unit cost, while prices drop significantly for orders of 1000 units or more. Large-scale orders help suppliers reduce unit production, packaging, and shipping costs—and they’re willing to pass those savings on to buyers.Capacity-Based Pricing

Higher-capacity batteries usually come at a higher price. For instance, a 3500mAh 18650 battery will cost more than an 1800mAh one. That’s because achieving higher energy storage requires better materials and more advanced technology. When estimating your B2B procurement costs, consider the relationship between capacity and pricing, and strike a balance between power requirements and cost-efficiency.4. Customization Options

Many manufacturers—including Apsen Technology—offer customization services for 18650 batteries, which is especially valuable for businesses with specific product needs.

Capacity and Discharge Rate Customization

If your application demands non-standard capacities or specific discharge rates, manufacturers can customize the battery cells accordingly. For example, if you need a 2200mAh battery or a higher discharge rate to power high-performance equipment, they can tailor the product through technical adjustments.Packaging and Label Customization

Manufacturers also offer custom packaging and labeling services. You can request packaging that fits seamlessly into your product assembly process. In addition, they can apply custom labels featuring your company logo, product specs, or branding—helping with both brand promotion and product identification.Final Thoughts

When purchasing 18650 batteries in bulk for your B2B operations, it’s essential to understand the product specifications, find a trusted manufacturer like Apsen Technology, and recognize the factors that influence pricing. With careful planning and supplier communication, you can secure a stable supply of high-quality 18650 batteries at competitive prices.

-

What is 18650 Flat Top Rechargeable Battery?

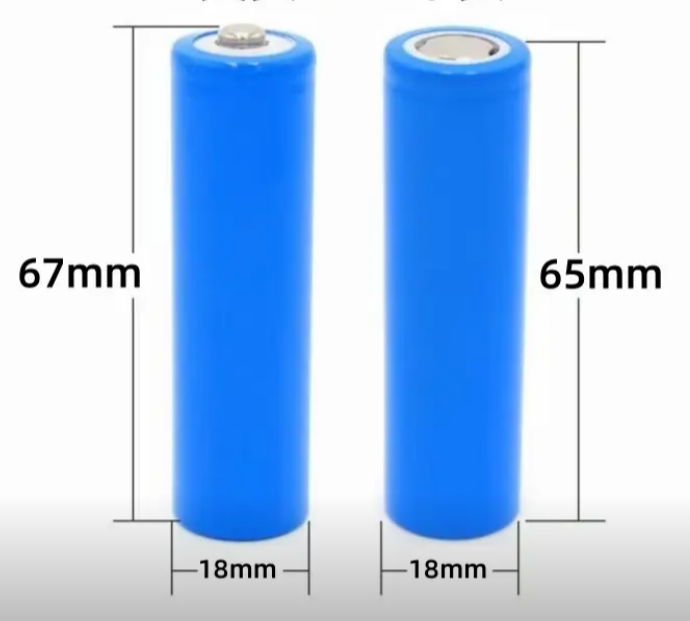

18650 battery comes in two forms based on the shape of the positive terminal: flat-top and button-top. These refer to the shape of the battery’s positive contact surface.

Flat-Top Battery:

18650 flat-top rechargeable battery features flat positive terminal. Devices such as flashlights, remote controls, and digital cameras commonly use flat-top batteries. This flat design allows the battery to make secure contact with the device’s terminals, ensuring stable current flow and reliable device operation.Button-Top Battery:

Button-top batteries, sometimes called “raised-head batteries,” have a protruding positive terminal. High-power devices like power tools, electric vehicles, and e-bikes often use button-top batteries. The raised terminal strengthens the connection between the battery and the device’s contacts during high-current discharges. This reduces contact resistance and prevents overheating or power loss caused by poor contact.Device Compatibility:

One key difference between flat-top and button-top batteries is device compatibility. Some devices require a specific terminal type. When purchasing batteries, users must check the device specifications to ensure they choose the right type.

No Major Chemical Differences:

Flat-top and button-top batteries don’t differ in chemistry or capacity. Both can come in various lithium chemistries, such as lithium manganese oxide (LiMn2O4), lithium cobalt oxide (LiCoO2), or lithium nickel manganese cobalt oxide (NMC). So, when selecting a battery, users should also consider the chemistry, capacity, and other technical specifications.Differences Between Flat-Top and Button-Top 18650 Batteries

Size and Shape:

The positive terminal of a flat-top 18650 battery is smooth and flat, while the button-top version extends about 3 millimeters higher with a visible bump. This bump helps prevent short circuits by reducing the chance of unintended contact between the battery’s positive terminal and conductive materials during installation or transport.Battery Characteristics:

Both types of batteries offer similar capacity and performance. They share the same 18mm diameter and can often be used interchangeably based on physical size and capacity. However, most button-top 18650 batteries include a built-in protection circuit that monitors voltage and current. This circuit disconnects the battery if it detects overcharging, over-discharging, or short-circuiting, providing full protection for both the battery and device. In contrast, flat-top batteries usually lack this protection and rely on the device to provide safety features.When selecting a battery, users should match the battery shape and features with their device’s requirements. The 18650 battery remains highly popular thanks to its excellent performance and wide range of applications. To ensure safe and efficient use, it’s essential to consider factors such as capacity, continuous discharge current, internal resistance, voltage, safety features, temperature tolerance, and cycle life. Choosing the right 18650 battery helps ensure the reliable performance and safety of your device.

-

How to Upgrade Your Drone Battery for Better Flight Performance

- Identify the Battery Type and Specifications Before upgrading the battery, you need to understand the type and specifications of the battery your drone uses. You can check the drone’s user manual or visit the manufacturer’s website for this information.

- Choose the Right Battery Once you know the type and specifications, you can select a battery that is compatible with your drone. Generally, a larger capacity battery will provide longer flight time, but it may also increase the drone’s weight, which could affect stability.

- Replace the Battery After selecting the appropriate battery, you need to remove the old battery and install the new one. Be sure to check the battery polarity before installation, as incorrect polarity may prevent the drone from starting or cause a short circuit.

- Choose Reliable Battery Supplier When upgrade your battery, make sure to choose trusted manufacturer. Avoid buying low-quality batteries, as these could damage the drone or cause safety hazards.

- Ensure Safe Charging Before using the new battery, confirm that the charger is compatible and that neither the charger nor the battery shows signs of damage. Always follow the manufacturer’s instructions during charging to avoid overcharging or short circuits.

- Calibrate the Battery After replacing the battery, it’s essential to calibrate the drone’s battery. Follow the instructions in the user manual to complete the calibration process.

-

How to Choose the Right Power Battery for Your Drone?

If you know a few basics about drone batteries — like the types, connectors, and key specs — it becomes much easier to pick the right one for your drone.

Types of Drone Batteries

There are a few types of batteries commonly used in drones:

- Nickel-metal hydride (NiMH) batteries

- Cylindrical lithium-ion batteries

- Lithium polymer (LiPo) batteries

- Lithium iron phosphate (LiFePO₄) batteries

Which one you need mainly depends on the type of drone you’re using.

For drones that aren’t super picky about weight or power output, you might see standard 18650 lithium-ion batteries or even NiMH batteries being used.

But these days, most drones run on soft-pack LiPo batteries.

That’s because LiPo batteries are lighter, pack more energy, offer bigger capacity, and can handle high discharge rates — perfect for fast, exciting drone flying!

Drone Battery Wires and Connectors

Drone batteries come with different wires and connectors, depending on how much power they need to deliver.

Common wire sizes include 8, 10, 12, 14, 18, 20, and 22 AWG (basically, the thickness of the wire).

The connector type depends on the current you need. Two popular ones are XT60 and T-plug connectors.- XT60: Highly recommended! It can handle around 60 amps of current.

- T-plug: Shaped like the letter T, and usually supports up to 20 amps.

If you’re not sure, XT60 is usually safe bet.

Key Specs for Drone Batteries

When picking drone battery, keep eye on a few important numbers:

- Capacity

- Voltage

- Discharge rate (how much current it can safely deliver)

- How the battery cells are wired together (series or parallel)

Once you understand these, choosing the right battery becomes much easier — especially if you’re into building or tweaking your own drones.

Generally, you want battery that offers high capacity, can handle high current, and stays as small and light as possible.A good choice for performance would be high C-rate LiPo battery.

Storing Drone Batteries

When you’re not using your batteries, store them somewhere dry and well-ventilated.

Lithium batteries naturally lose charge over time, and heat or humidity can speed that up.

Try to keep them at temperature between -10°C and 45°C (14°F to 113°F).If you’re storing them for long time (like more than 3 months), aim for a place around 23°C (73°F) with about 65% humidity.

Also, give them recharge every three months to prevent the battery from draining too low, which can cause permanent damage. -

What Is ICR 18650 Lithium Battery?

The ICR 18650 lithium battery is a cylindrical battery with a diameter of 18mm and a height of 65mm. The “18650” refers to its size specification, while “ICR” indicates the type of lithium-ion battery. On the battery label, “ICR” represents its chemical composition and performance features.

These batteries are known for their high energy density, long cycle life, and low self-discharge rate. Because of these traits, they are widely used in consumer electronics, electric vehicles, and power tools.

The typical capacity of an ICR 18650 lithium battery ranges from 1800mAh to 3500mAh, with a nominal voltage of about 3.7V. They offer excellent charge/discharge performance, support fast charging, and can reliably meet the high-power demands of modern devices.

Application Fields of ICR 18650 Lithium Batteries

Thanks to their performance and stability, ICR 18650 batteries are applied in a wide range of electronic products.

- Electric mobility: electric vehicles (EVs), hybrid electric vehicles (HEVs), e-bikes, and electric scooters.

- Power tools: drills, saws, and other equipment that need continuous, reliable power.

- Portable electronics: laptops, camcorders, flashlights, and other lightweight devices that require compact yet long-lasting energy sources.

Their compact size combined with strong performance makes them one of the most versatile lithium battery types available.

Relationship Between ICR 18650 Lithium Batteries and Power Batteries

Power batteries are mainly designed to provide propulsion energy, often used in EVs, HEVs, and other high-power devices like electric bicycles. In many cases, ICR 18650 batteries can serve as power batteries due to their:

- High energy density

- Stable charging/discharging performance

- Long service life

This makes them a strong option for applications that demand both endurance and high power output.

However, not every ICR 18650 cell is suitable for heavy-duty or high-power use. Factors such as discharge rate, cycle life, and temperature resistance determine whether a specific ICR battery can reliably function as a power battery.

Differences Between ICR and INR Batteries

There is often confusion between ICR and INR batteries, but they are not the same.

- INR Batteries

INR lithium-ion rechargeable batteries typically use cathode materials like lithium manganese oxide, lithium cobalt oxide, nickel-cobalt-manganese (NCM), or lithium iron phosphate.- High energy density

- Safer and more stable compared to ICR

- Support fast charging and higher current handling

- Commonly used in laptops, cameras, drones, and other consumer electronics requiring long runtime and consistent energy output

- ICR Batteries

ICR batteries are designed for high-rate discharge applications.- Cathode: often lithium cobalt oxide (LCO) or nickel-cobalt-aluminum oxide (NCA)

- Anode: typically graphite or other carbon-based materials

- Can deliver high current quickly, making them ideal for demanding tools and equipment

- Widely applied in:

- Power tools

- Robot vacuums and household appliances

- Drones and RC models

- High-speed electric motorcycles

- Hybrid new energy vehicles

- Industrial and commercial energy storage

- Frequency regulation systems and UPS backup power

In short, ICR batteries excel at delivering bursts of high current, while INR batteries balance energy density, safety, and versatility.

-

How to Assemble Lithium Battery Cells into Battery Pack

The process of assembling lithium battery cells into a complete battery pack is called battery PACK. It involves integrating key parts such as the cells themselves, a protection board, nickel strips, and labeling materials. Through a series of processing and assembly steps, these components are combined into a fully functional battery pack.

Let’s go step by step and see how a lithium battery pack is designed and assembled.

What is a Lithium Battery Pack?

A lithium battery pack is essentially a circuit system made up of multiple lithium cells that work together to store and deliver energy.

Each pack can contain several cells, and each cell comes with its own voltage and capacity. By connecting cells in series or parallel, the pack can be configured to deliver either higher voltage or greater capacity. A charging system is typically built into the pack to supply energy to devices.

The size of a pack depends on the number and type of cells it contains. Common formats include 18650, 21700, 26650, 32700, and prismatic cells. The number of cells used directly influences the pack’s final size.

Step 1: Cell Sorting and Grouping

The first step is to sort and match the cells. Technicians group cells with similar characteristics to ensure consistency. Key parameters include:

- Internal resistance

- Voltage

- Rated capacity

- Charge/discharge efficiency

- Self-discharge rate

By grouping similar cells together, internal balance is improved, efficiency is higher, and the battery pack’s service life is extended.

Step 2: Cell Assembly and Fixture Alignment

The sorted cells are placed into structured fixtures and then spot welded together. Following the Standard Operating Procedure (SOP) is critical at this stage, especially ensuring correct polarity alignment (positive and negative terminals).

Proper alignment avoids short circuits and ensures electrical safety.

Step 3: Welding the Battery Pack to the PCM/BMS

Next, the cells are welded to a PCM (Protection Circuit Module) or a BMS (Battery Management System). This is essentially the “brain” of the pack.

It protects the battery from:

- Overcharging

- Over-discharging

- Short circuits

For low-voltage packs (<20 cells), a PCM with balancing features is often enough. For high-voltage packs (>20 cells), a BMS is essential, since it continuously monitors the cells to maintain safe operation.

Step 4: Insulating the Semi-Finished Pack

At this stage, insulation materials are applied and voltage sensing wires, output cables, and positive/negative terminals are secured.

⚠️ Care must be taken to avoid compressing or stacking wires, especially voltage sampling wires. Pressure on these can damage insulation and increase the risk of short circuits. Proper insulation ensures safe handling before the final assembly.

Step 5: Testing the Semi-Finished Pack

The semi-assembled battery is now tested for quality and performance. Typical tests include:

- Charge/discharge cycles

- Internal resistance checks

- Capacity measurements

- Safety tests (overcharge, over-discharge, short-circuit, overcurrent)

Depending on the application, additional stress tests may also be performed—such as high/low-temperature testing, nail penetration, drop resistance, and salt spray corrosion.

During these tests, technicians closely monitor how the battery responds. For example:

- In overcharge tests, they verify if the BMS safely handles high voltage.

- In short-circuit tests, they check whether the system can manage sudden current surges.

- In overcurrent tests, they see how well the BMS manages strong pulse currents.

Only after passing all tests does the pack move on to packaging.

Step 6: Battery Pack Packaging

The packaging method depends on the pack design.

- For PVC-wrapped packs, a heat-shrinking machine is used.

- For metal case packs, external casing is assembled.

Throughout the process, the battery must be handled carefully to avoid impact or compression. Proper insulation of wires is also crucial to prevent shorts..

Step 7: Final Pack Testing

In the last stage, the completed pack is tested on a comprehensive battery tester. Parameters such as:

- Total voltage

- Internal resistance

- Charge/discharge performance

are verified. If necessary, additional protection tests (short-circuit, overcurrent) are also carried out to ensure full safety.

Final Thoughts

After these steps, the lithium battery pack is fully assembled and ready for use. While the process may sound complicated, following each step carefully ensures a pack that is both safe and reliable, tailored to its intended application.

-

What is good 18650 battery,How to Choose High-Quality 18650 Lithium Battery?

Choosing 18650 lithium battery isn’t as complicated as it might seem. Once you understand a few key points, picking out a reliable, high-quality battery becomes much easier.

Battery Capacity

Capacity plays the biggest role in determining how long a battery can power your device on a single charge. The higher the capacity, the longer the runtime—making it especially important for devices that demand extended power supply.

Most 18650 batteries have capacities ranging from 2000mAh to 3500mAh, while premium models can reach up to 3600mAh.

Cycle Life

Another major factor is cycle life, which tells you how many times the battery can be charged and discharged before its performance starts to drop. A longer cycle life means fewer replacements over time.

A good-quality 18650 lithium battery should last for at least 500–1000 charge cycles.

Internal Resistance

Internal resistance often gets overlooked, but it has a big impact on performance. Batteries with lower resistance deliver more stable current output, waste less energy, and run more efficiently.

This is especially important for high-drain applications like power tools, e-bikes, and flashlights, where consistent performance is key.

Final Thoughts

When choosing an 18650 lithium battery, pay close attention to capacity, cycle life, and internal resistance. These three factors together will help you select a battery that’s not only powerful but also durable and efficient.

-

why do drones use lipo batteries

Drone batteries come in different types, each with its own strengths and limitations depending on the drone’s purpose. Here’s a breakdown of the most common options and where they are typically used.

Lithium Batteries

Advantages: These batteries offer high energy density, are lightweight, charge quickly, last a long time, and don’t suffer from memory effect.

Disadvantages: They cost more than other options, require strict charging and discharging control, and can be damaged by overcharging or deep discharging.

Application Scenarios: A great choice for mid-to-high-end drones, especially models that focus on being lightweight and having long flight endurance.

Lithium Polymer Batteries (LiPo)

Advantages: LiPo batteries are essentially an improved version of standard lithium batteries. They have higher energy density, weigh less, self-discharge more slowly, charge quickly, and offer long service life—making them an excellent energy solution.

Disadvantages: They are relatively expensive and need special protection circuits to operate safely.

Application Scenarios: Commonly found in small to medium-sized drones. They are especially useful for drones that need to carry extra batteries or equipment to extend flight time or handle additional payload.

Nickel-Metal Hydride Batteries (NiMH)

Advantages: Affordable, long-lasting, and more environmentally friendly than some alternatives.

Disadvantages: They have lower voltage, heavier weight, smaller capacity, and a higher self-discharge rate compared to lithium-based batteries.

Application Scenarios: Mostly used in entry-level or budget drones, making them suitable for beginners or users who don’t want to invest heavily.Sealed Lead-Acid Batteries (SLA)

Advantages: Known for being inexpensive and reliable.

Disadvantages: Bulky, heavy, and with low energy density, they are not ideal for long flights or high-power needs.

Application Scenarios: Sometimes used in larger drones or for specific purposes, such as agricultural spraying drones.Why Do Drones Use LiPo Batteries?

LiPo batteries are built with polymer electrolytes, lithium-based electrodes, and separators. Compared with older liquid electrolyte lithium batteries, they provide higher energy density, improved safety, and longer lifespan.

This is why LiPo batteries have become the go-to option for drones. They help extend flight time and make drones more reliable for demanding uses like aerial photography, security monitoring, agriculture, and even search and rescue missions. Their enhanced safety profile also makes them more dependable in real-world applications.

Looking ahead, graphene batteries could eventually become a powerful alternative for drones. But since the technology is still developing, they remain a future possibility rather than a current solution.

-

What is the Best 18650 Rechargeable Battery?

Understanding 18650 Rechargeable Batteries

In today’s world of advanced technology and portable devices, the demand for reliable and high-performance rechargeable batteries is growing. Among the many options, the 18650 rechargeable battery stands out for its versatility and popularity.

So, what makes a battery the best 18650 rechargeable battery? To answer that, we need to look at several key factors.

Capacity

One of the most important aspects to consider is battery capacity. Higher capacity batteries provide longer runtimes for your devices, meaning you won’t have to recharge as often.

Look for 18650 batteries with capacities ranging from 2500mAh to 3500mAh or even higher. Keep in mind that higher capacity can sometimes mean larger size and weight, so choose according to your device’s requirements.

Discharge Rate

The discharge rate determines how much power a battery can deliver at any given time. For devices that demand high power output—like flashlights or power tools—a battery with a high discharge rate is essential.

Look for labels such as “high drain” or “continuous discharge” to ensure the battery can handle intensive use.

Brand and Quality

The brand and quality of the battery make a big difference. Trusted brands tend to produce batteries that meet strict quality standards and provide reliable performance.

Well-known names in the 18650 battery market include Panasonic, Samsung, and LG. These brands are known for:

- Advanced battery technology

- Consistent quality

- Excellent customer support

Safety Features

Safety is another crucial consideration. 18650 batteries can be dangerous if not manufactured or used properly.

Look for batteries with built-in safety features like:

- Overcharge protection

- Over-discharge protection

- Short-circuit protection

These features help prevent accidents and ensure both battery and user safety.

Price Considerations

While it may be tempting to choose the cheapest option, balance price with quality. A higher-quality 18650 battery may cost more upfront but can save money over time by providing:

- Longer lifespan

- Better performance

- Reduced risk of failure or safety issues

Choosing the Right Battery

The best 18650 battery depends on your specific needs:

- High-power devices: Prioritize a high-drain battery from a reputable brand.

- Long runtime and portability: Choose a high-capacity battery with good safety features.

- General-purpose use: A mid-range battery balancing capacity, discharge rate, and safety is often ideal.

Always purchase from reliable sources to ensure authenticity and quality.

Conclusion

In summary, the best 18650 rechargeable battery is one that fits your needs in terms of capacity, discharge rate, brand quality, safety, and price.

By taking the time to research and compare options, you can choose a battery that powers your devices reliably and provides long-lasting performance. With the right 18650 battery, you can enjoy peace of mind knowing your devices will operate efficiently and safely for a long time to come.

-

what size are 1.5v bateries

What is a 1.5V Lithium Battery?

A 1.5V lithium battery is a rechargeable lithium-ion battery that maintains a constant voltage of 1.5V throughout its entire discharge cycle without any drop. Internally, it uses a 3.6V lithium-ion cell, and through built-in circuitry, it regulates the output voltage to achieve 1.5V. This design provides strong power capabilities, making it ideal for devices that demand high current and voltage.

1.5V lithium batteries also support fast charging. For example, a single AA battery with a capacity of 3300mWh can fully charge in about 2 hours, whereas traditional nickel-metal hydride (NiMH) batteries may take around 10 hours.

Types of 1.5V Batteries

- No. 1 Battery (D-type)

- Voltage: 1.5V

- Current: 1A

- Dimensions: Diameter 32.2mm, Height 59mm

- Short-circuit current: 1.5–2A

- No. 5 Battery (AA-type)

- Most commonly disposable alkaline batteries

- Voltage: 1.5V

- Capacity: 600–700 mAh (for alkaline)

- Rechargeable variants include NiMH, NiCd (phased out), and iron lithium batteries

- NiMH: up to 2700mAh at 1.2V

- Iron lithium: up to 3000mAh at 3.2V

- No. 7 Battery (AAA-type)

- Dimensions: Height 43.6 ±0.5mm, Diameter 10.1 ±0.2mm

- Types: dry cells, lithium batteries, NiMH, NiCd

- Common alkaline AAA batteries (e.g., LR03)

- Voltage: 1.5V, Capacity: ~1300mAh

Note: No. 5 batteries generally exceed 1600mAh, while No. 7 batteries usually do not exceed 900mAh.

Can 1.5V and 1.2V Batteries Be Interchanged?

It depends on the device. Devices with higher voltage requirements may not operate efficiently with 1.2V batteries. The key difference is that 1.2V batteries are rechargeable, while 1.5V batteries can be either rechargeable or disposable, depending on the type.

Advantages of 1.5V Lithium-Ion Batteries

Modern devices require reliable, rechargeable power sources. Disposable batteries are becoming less popular as many devices rely on electricity, making rechargeable lithium-ion batteries more practical and cost-effective.

Compared to NiMH batteries:

- Capacity does not fluctuate with charge state

- After repeated charging cycles, 1.5V lithium-ion batteries maintain about 80% capacity after 500–1000 cycles

- Reduce long-term operational costs

Before lithium-ion batteries, disposable alkaline batteries powered 1.5V devices. Lithium-ion batteries quickly replaced them due to rechargeability, eliminating the need for repeated battery replacements.

Environmental benefits:

- Reduce spent battery waste

- Minimize toxic materials such as mercury, lead, cadmium, and nickel in the environment

- Recyclable and more sustainable than disposable alternatives

Applications of 1.5V Lithium-Ion Batteries

1.5V lithium-ion batteries are widely used in daily life, powering:

- Small electronic devices (AA/AAA lithium-ion batteries)

- Household appliances

- Vehicles

- Hybrid and renewable energy storage systems

As the world shifts toward green energy from fossil fuels, 1.5V lithium-ion batteries will play an increasingly critical role. They are rechargeable up to 500–1000 times, which is roughly equivalent to 1000 disposable batteries, making them both economical and environmentally friendly.

Advancements in 1.5V Lithium-Ion Batteries

Ongoing research is improving the performance of 1.5V lithium batteries through new chemistries and designs, including:

- Lithium-sulfur

- Lithium-air

- Sodium-ion batteries

- Solid-state lithium batteries

- Lithium-ion solar batteries for higher energy density, lighter weight, and longer lifespan

These advancements allow 1.5V lithium-ion batteries to integrate with solar photovoltaics and other renewable energy technologies, further supporting sustainable energy solutions.