If you’ve ever thought about building a high-capacity battery pack, the question “how many 18650 batteries are needed for 100Ah?” inevitably comes up. It sounds simple—just divide 100Ah by the capacity of a single cell—but anyone who has tried this in practice knows it’s more complex. Voltage, series and parallel connections, chemistry differences, and safety considerations all play a role.

Understanding 18650 Batteries and Their Capacity

The 18650 lithium-ion battery is a standard cell, about 18mm in diameter and 65mm long, usually rated at 3.6V–3.7V, with capacities ranging from 1500mAh to 3500mAh.

For instance, a 2500mAh cell can supply 2.5A for an hour, or 1.25A for two hours.

That’s the nominal figure. Real-world performance depends on temperature, age, and discharge rate, so calculating a 100Ah pack is never just a straight division.

Series vs Parallel Connections

This is where the design gets interesting. Series connections boost voltage, while parallel connections increase capacity:

- Series (S): Connect cells end-to-end; voltage adds up. For example, three 3.7V cells in series give 11.1V nominal.

- Parallel (P): Connect cells side-by-side; capacity adds up. Ten 2.5Ah cells in parallel = 25Ah at 3.7V.

The total number of cells = Series × Parallel.

Notice the subtlety: achieving 100Ah isn’t just about capacity. Voltage requirements determine series count, which then shapes total hardware needs.

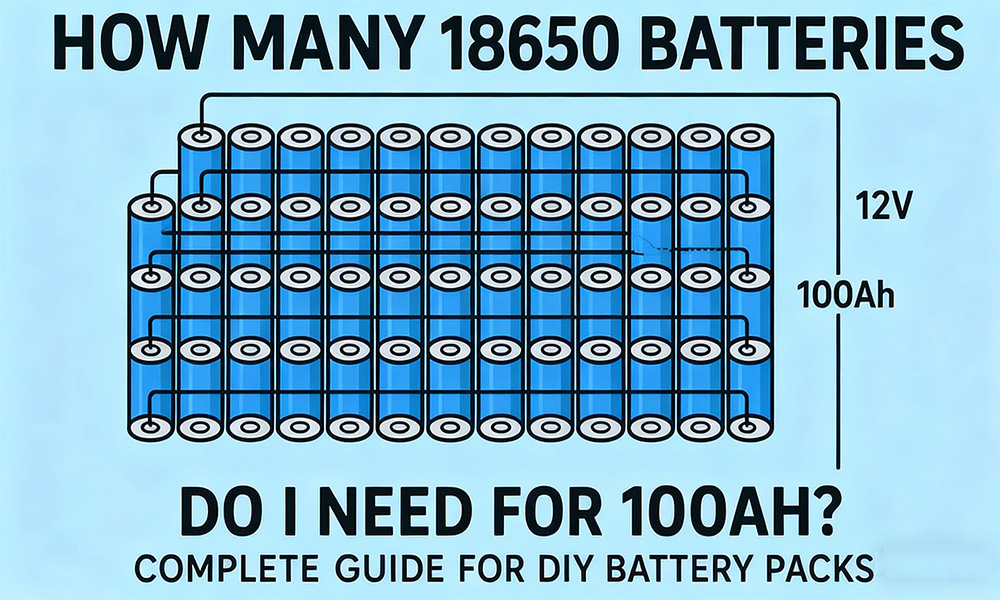

Step-by-Step Example: 12V / 100Ah Pack

Let’s assume you want 12V / 100Ah battery pack using 3.7V, 2500mAh cells:

- Series count (S): 12 ÷ 3.7 ≈ 3 → 3 cells in series (3S).

- Parallel count (P): 100 ÷ 2.5 = 40 → 40 cells in parallel (40P).

- Total cells: 3 × 40 = 120 cells.

Here’s the thought process in action: first voltage, then capacity, finally total cells. This layered thinking is what separates theoretical calculation from practical design.

How Different Cells Change the Calculation

| Cell Spec | Pack Voltage | Series (S) | Parallel (P) | Total Cells |

|---|---|---|---|---|

| 3.7V / 2500mAh | 12V | 3 | 40 | 120 |

| 3.7V / 3000mAh | 12V | 3 | 34 | 102 |

| 3.7V / 3500mAh | 12V | 3 | 29 | 87 |

| 3.2V / 1500mAh LiFePO₄ | 12V | 4 | 67 | 268 |

Even small changes in capacity or chemistry can shift total cell count significantly. Relying solely on Ah numbers can be misleading.

Practical Considerations

- Cell Consistency: Cells should have similar capacity, chemistry, and internal resistance. A single weak cell can drag down the whole pack.

- Battery Management System (BMS): Vital for monitoring voltage, temperature, and charge/discharge balance. Protects against overcharging and overdischarging.

- Safety: Large parallel packs require proper fuses, wiring, and thermal management.

- Capacity Margin: Aging, heat, and actual load may reduce usable Ah, so slightly exceeding 100Ah in design is wise.

Key Takeaways

- A 12V, 100Ah pack using 2500mAh cells generally requires about 120 cells.

- Higher-capacity cells reduce total cell count; lower-capacity or different chemistry cells may more than double it.

- The process is layered: determine voltage first, capacity second, safety and real-world adjustments third.

This approach ensures that your battery pack not only meets the 100Ah target but also performs reliably under real conditions.

Recommend Products

-

12V 4400 mah Lithium ion 3S2P 18650 Battery Pack

-

18650 2000mAh 3.7 volt Lithium-ion Battery

-

18650 20V 3.0Ah Cordless Drill battery

-

18650 22.2V 7.8Ah 2600Mah 6S3P Rechargeable Battery Pack

-

18650 3.7V 10Ah Li-Ion Power Battery Pack

-

18650 3.7V 3300mah Rechargeable Lithium ion Battery

-

18650 7S7P 24V 14Ah Lithium ion Electric Scooter Battery Pack

-

18650 battery 3.7V 1500mAh Lithium-Ion Battery

-

18650 Electric Scooter 48V 13000mAh Lithium Battery

-

2600mAh 3S1P 11.1V 18650 Battery Packs

-

3.7V Li ion Rechargeable 3000mah 18650 Battery Cell

-

36V 5200mAh 10S2P 18650 Battery Pack

-

48v 4400mah 13S2P 18650 Rechargeable Battery Pack

-

7S2P 24V 18650 Lithium Battery Pack

-

Electric Scooter 36V 4400mAH 10S2P 18650 Battery Pack

-

ICR 18650 Battery 2200mah 3.7V

Leave a Reply